A ball joint allows the wheels to move up and down while also steering the vehicle. It consists of a spherical bearing and a socket that allows for rotational movement in all directions. This essential component connects the control arm to the steering knuckle, enabling smooth and controlled motion of the front wheels.

A ball joint’s design provides flexibility and support, allowing the suspension to absorb shocks and maintain stability during cornering and uneven road conditions.

As a result, proper maintenance and regular inspections of ball joints are crucial for ensuring safe and efficient vehicle performance.

The Basics Of Ball Joints

Bold Phrases: A ball joint plays a crucial role in the suspension system of a vehicle. It connects the steering knuckles to the control arms and allows for the flexible movement of the suspension. This vital component withstands the weight of the vehicle while enabling the wheels to move in various directions.

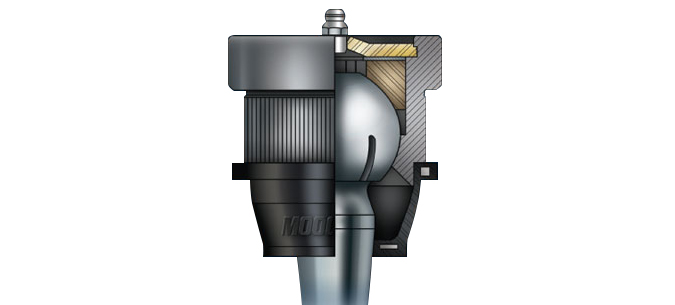

Essentially, a ball joint acts as a pivot point, accommodating the vertical and lateral movements of the suspension and steering systems. It is composed of a housing, a ball stud, bearings, and a socket, all of which work together to facilitate smooth and controlled movements.

The proper functioning of ball joints is integral to maintaining the stability and control of a vehicle, ensuring safe handling and optimal performance. Worn-out ball joints can lead to excessive tire wear, steering instability, and compromised vehicle safety.

Regular inspection and maintenance of ball joints are essential to prevent potential issues and ensure the overall functionality of the vehicle’s suspension.

Credit: www.moogparts.com

How Does A Ball Joint Work

The structure and mechanism of ball joints enable the smooth operation of a vehicle’s steering and suspension system. These crucial components facilitate the connection between the control arms and steering knuckles, allowing for the articulation and movement of the wheels.

There are various types of ball joints utilized in automotive systems, including load-bearing, follower, and combination ball joints, each serving specific functions based on the vehicle’s design and performance requirements.

Components And Functioning Of Ball Joints

Ball joints are crucial components in a vehicle’s suspension system manufactured from high-quality materials such as steel and aluminum.

These components connect the control arms to the steering knuckles, allowing for articulation and movement. The articulation of ball joints facilitates smooth turning and maneuvering of the vehicle. Additionally, they play a pivotal role in bearing heavy loads and absorbing shocks.

This load-bearing capability ensures the stability and balance of the vehicle, while the shock absorption capability enhances the comfort of the ride for the occupants.

It is evident that the construction and materials of ball joints, as well as their movement and load-bearing capabilities, are essential for the optimal functioning of a vehicle’s suspension system.

Different Types Of Ball Joint Configurations

Ball joints are crucial components in vehicle suspension systems, responsible for connecting the control arms to the steering knuckles. There are various configurations of ball joints, including pinch-ball joints, threaded-ball joints, and press-in-ball joints.

These different types exhibit unique characteristics in different vehicle systems, influencing the overall performance of the vehicle. It’s important to understand the variations in ball joint designs to ensure proper functionality and safety.

Each configuration comes with its own set of pros and cons, which include factors such as durability, ease of installation, maintenance requirements, and cost effectiveness.

By considering these aspects, vehicle owners can make informed decisions when it comes to choosing the appropriate ball joint configuration for their specific requirements.

Importance Of Ball Joint Maintenance And Replacement

Signs of Worn Out Ball Joints: It’s important to be aware of the signs of worn out ball joints, such as irregular tire wear, clunking or knocking noises while driving, and wandering steering. These symptoms indicate the need for inspection and potential replacement.

Inspection and Maintenance Guidelines for Ball Joints: Regular inspection of ball joints is crucial for detecting signs of wear and ensuring proper maintenance. This includes checking for excessive play or looseness, torn boots, and rust. Maintenance should involve greasing the joints as per the manufacturer’s recommendations.

Process of Replacing Faulty Ball Joints: When it’s necessary to replace faulty ball joints, the process involves lifting the vehicle, removing the wheels, control arms, and old ball joints, and installing new ones. Proper torque specifications and alignment are essential for a successful replacement.

Conclusion

How a ball joint works is essential for vehicle maintenance. Regular inspections and timely replacements can ensure smooth driving and prevent premature wear and tear. By grasping the basic functions of a ball joint, you can prolong your vehicle’s lifespan and ensure its safety on the road.