Ever wondered just how tight you should secure the lug nuts on your vehicle’s wheels? It’s a common question with critical implications.

Getting the right torque is crucial not only for your safety but also for the longevity of your wheels and tires. Too loose, and your wheels might wobble; too tight, and you risk damaging the wheel studs. Understanding the correct number of foot-pounds (ft-lbs) for lug nuts can save you from potential headaches and costly repairs.

You’ll uncover the precise torque specifications you need to ensure your wheels are securely and safely fastened. Stick around, because what you learn could make all the difference in your next drive.

Credit: www.tirerack.com

How Many Ft Lbs Of Torque On Lug Nuts

Tightening lug nuts requires 80 to 100 ft-lbs of torque for most vehicles. Check your car’s manual for specifics. Proper torque ensures safety and prevents wheel damage.

Understanding the correct torque for lug nuts is crucial for vehicle safety. Applying the right amount of force ensures your wheels are secure. Too much or too little torque can lead to problems on the road. Let’s explore how many foot-pounds are recommended for lug nuts.

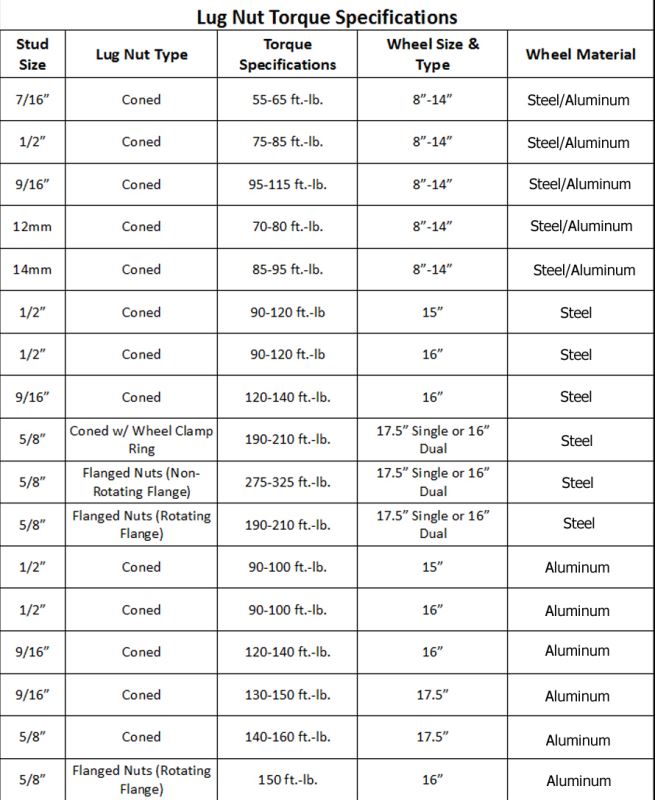

Standard Torque for Lug Nuts Many people wonder about the standard torque for lug nuts. It varies based on the vehicle. Here’s a closer look: – Passenger cars: Usually require 80 to 100 ft-lbs. – Light trucks: Typically need 100 to 120 ft-lbs.

– Heavy trucks: Often demand 120 to 140 ft-lbs. – Motorcycles: Generally need 40 to 60 ft-lbs. Factors Influencing Torque Requirements Several factors can affect the required torque for lug nuts. Keep these in mind: – Wheel material: Alloy wheels may have different needs than steel ones.

– Bolt size: Larger bolts often need more torque. – Manufacturer specifications: Always check your vehicle’s manual. – Climate: Temperature changes can influence torque settings. Importance of Correct Torque Correct torque is vital for several reasons. Ensuring accuracy prevents wheel issues: – Wheel security: Proper torque keeps wheels firmly attached.

– Preventing damage: Over-torquing can damage threads. – Safety: Avoids wheel detachment during driving. – Fuel efficiency: Properly torqued wheels can improve efficiency. Tools for Measuring Torque Using the right tools helps achieve the correct torque. Consider these options: – Torque wrench: Most common and precise tool.

– Impact wrench: Useful for quick adjustments. – Digital torque adapter: Converts any wrench into a torque tool. – Beam torque wrench: Simple and reliable. Checking and Maintaining Torque Regular checks ensure your lug nuts remain secure. Here’s how to maintain them: – Re-torque after installation: Check torque after driving a few miles.

– Regular inspections: Periodically check lug nuts for looseness. – Use proper tools: Always use a torque wrench for accuracy. – Follow guidelines: Stick to manufacturer-recommended settings.

Credit: popupportal.com

Conclusion

Choosing the right torque for lug nuts is crucial. Proper torque ensures safety and efficiency. Use a torque wrench for precision. Too tight or too loose can cause problems. Check your vehicle’s manual for exact specifications. Different vehicles require different torque levels.

Regular checks prevent issues on the road. Proper maintenance extends wheel life. Always tighten in a star pattern. This avoids uneven pressure. Remember, safety first. Proper torque keeps wheels secure. Simple steps make a big difference. Happy driving!