Imagine transforming the used motor oil sitting in your garage into a valuable resource. Yes, you can actually clean and repurpose it as fuel.

This not only saves you money but also helps protect the environment. You might be wondering how to do this safely and effectively. You’re not alone. Many people are seeking ways to make the most out of what they already have.

In this guide, you’ll discover simple steps to clean used motor oil, making it fit for use as fuel. Stay with us, and you’ll learn how to turn what was once waste into something incredibly useful. Your wallet and the planet will thank you.

Benefits Of Recycling Motor Oil

Recycling used motor oil can bring several benefits to the environment and economy. By cleaning and reusing motor oil as fuel, we can reduce waste and promote sustainability. This process not only helps to conserve resources but also offers economic advantages.

Environmental Impact

Recycling motor oil reduces pollution. It prevents oil from contaminating soil and water. Clean, reused oil lowers emissions compared to burning new oil. Protecting ecosystems and wildlife becomes easier with reduced waste. Used oil recycling supports cleaner air and water.

Cost Savings

Using recycled motor oil saves money. It costs less than buying new oil. Businesses and individuals can cut fuel expenses significantly. Recycled oil can be a budget-friendly option. Saving money on fuel helps manage financial resources better.

Credit: recyclingpyrolysisplant.com

Safety Precautions

Ensure proper ventilation to prevent inhaling harmful fumes while cleaning motor oil. Wear protective gloves and goggles for safety. Dispose of waste responsibly to avoid environmental damage.

Cleaning used motor oil for fuel is a practical way to recycle and save money. However, it’s crucial to prioritize safety throughout the process. Handling used motor oil can pose health risks due to its contaminants, and taking proper precautions is essential to protect yourself and the environment. Are you aware of the potential hazards and how to safeguard against them? Let’s dive into some key safety measures.Protective Gear

Always wear appropriate protective gear to shield yourself from harmful substances in used motor oil. Equip yourself with safety goggles to protect your eyes from splashes. Use rubber gloves to prevent skin contact, as motor oil can cause irritation or allergic reactions. Consider wearing a long-sleeved shirt and pants to cover your skin, reducing the risk of exposure. If you’re working in a poorly ventilated area, a respirator mask can help protect your respiratory system from harmful fumes. Remember, safety gear is your first line of defense.Handling Contaminants

Used motor oil can contain various contaminants, including heavy metals and chemicals. Be mindful of these as you work. Make sure to use a well-ventilated space to reduce inhalation risks. Store the oil in a sturdy container to prevent spills and leaks. This is crucial to avoid environmental damage. If a spill occurs, clean it immediately using absorbent materials like sand or kitty litter. Dispose of any waste materials responsibly. Local waste management facilities often provide guidelines on disposing hazardous materials. Following these steps not only protects you but also keeps your surroundings safe. Have you considered how these precautions can affect the quality of your cleaned oil? Keeping safety front and center ensures a more efficient and effective process.Collection Methods

Cleaning used motor oil for fuel is a sustainable practice. Proper collection methods ensure success. Efficient collection preserves oil quality and prevents contamination. This section explores effective collection techniques. Proper drainage and storage are crucial for safe handling.

Drainage Techniques

Drain oil using a clean, wide-mouthed funnel. This prevents spills. Ensure the engine is slightly warm. Warm oil flows more easily. Use a drain pan with a spout. It helps transfer oil without mess. Avoid using tools that can damage the oil pan. This maintains oil integrity. After draining, seal the container tightly. This prevents dust and debris contamination.

Storage Solutions

Choose a sturdy, leak-proof container for storing used oil. Label it clearly. This avoids accidental misuse. Store oil in a cool, dry place. Heat degrades oil quality. Keep containers off the ground. This prevents moisture seepage. Regularly check containers for leaks. Transfer oil to a larger storage tank if needed. This is vital for large quantities.

Credit: usfiltermaxx.com

Filtration Process

Cleaning used motor oil for fuel involves a careful filtration process. Begin by heating the oil to remove water and impurities. Then, filter through layers to separate contaminants, ensuring cleaner, reusable fuel.

Cleaning used motor oil for fuel is a meticulous process that involves several key steps, with filtration being one of the most crucial. The filtration process is the heart of transforming dirty oil into a usable fuel source. It ensures that impurities are removed, and the oil is pure enough to be used safely in engines. While it may seem like a daunting task, with the right tools and knowledge, you can effectively filter used motor oil at home. Let’s dive into the details and explore how you can achieve clean and usable fuel through effective filtration.Types Of Filters

Choosing the right filter can make all the difference in your oil filtration process. There are several types of filters you can use, each with its own advantages: – Gravity Filters: These filters use gravity to separate impurities from oil. They’re simple and effective for basic filtration needs. – Centrifugal Filters: Ideal for heavy-duty filtration, these filters spin the oil, forcing impurities to separate due to centrifugal force. – Mechanical Filters: These involve layers of material that physically trap particles. Consider using mesh filters for large debris and fine filters for smaller particles. Each type of filter serves a specific purpose. Your choice depends on the level of purity you need and the equipment available to you.Step-by-step Guide

Filtering used motor oil requires careful handling. Follow this step-by-step guide to ensure a clean output: 1. Prepare Your Equipment: Gather your filters, containers, and safety gear. Make sure everything is clean and ready to use. 2. Pre-Filter the Oil: Before using your main filter, pour the oil through a mesh screen to remove large debris. This step prevents clogging in finer filters. 3. Set Up the Filtration System: Place your chosen filter in a container that can hold the oil. Ensure it’s stable and won’t tip over. 4. Pour the Oil Slowly: Gradually pour the oil into the filter. Pouring too quickly can overwhelm the filter and reduce effectiveness. 5. Monitor the Process: Watch the oil as it passes through the filter. Adjust your pouring rate to maintain consistent flow and prevent overflow. 6. Check the Output: Once filtered, inspect the oil for clarity. If impurities remain, consider a second filtration using a finer filter. 7. Dispose of Waste Properly: Collect the waste materials and dispose of them according to local regulations. This step is crucial for environmental safety. Do you ever wonder how much cleaner your oil could be with the right filter? By following these steps, you ensure the oil is as pure as possible, ready for use in your engine. The satisfaction of seeing clean oil flow from your filter is unmatched. It’s empowering to know you’re making a difference, both in your vehicle’s performance and in reducing waste.Purification Techniques

Purifying used motor oil for fuel offers environmental benefits. It reduces waste and supports sustainability. This process involves several methods to remove impurities. These techniques ensure the oil is safe and effective as fuel. Understanding these methods can help you clean motor oil efficiently.

Chemical Treatment

Chemical treatment uses substances to neutralize contaminants in used oil. This method targets acidic compounds and heavy metals. Adding specific chemicals helps break down harmful elements. The oil becomes cleaner and more suitable for reuse. Filtering follows to remove the remaining particles.

Thermal Processing

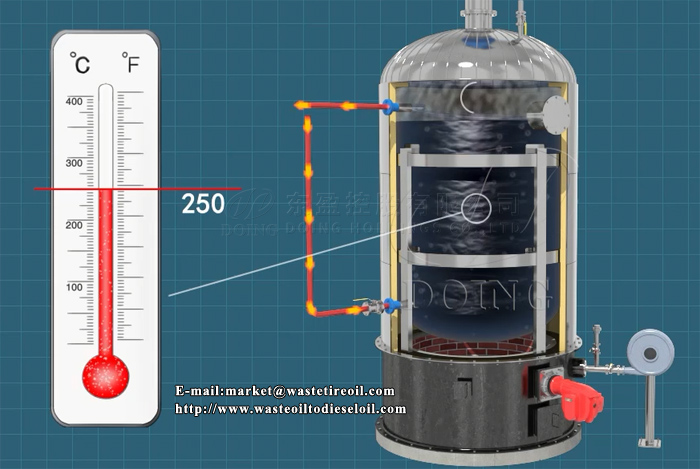

Thermal processing involves heating the used motor oil. This technique separates impurities through distillation. Heating the oil causes contaminants to evaporate. The clean oil remains behind, ready for use as fuel. Temperature control is crucial in this process. It ensures effective purification without damaging the oil.

Quality Testing

Quality testing is crucial in transforming used motor oil into fuel. It ensures the fuel is safe and efficient for use. Without proper testing, impurities may remain, affecting performance and safety. Every batch needs thorough testing to meet strict standards. Let’s delve into the tools and guidelines for quality assurance.

Testing Equipment

Specialized equipment assesses the quality of processed motor oil. A spectrometer identifies chemical compositions. It helps detect harmful substances. Viscosity testers measure the thickness of the oil. This is vital for engine compatibility. Flash point testers check the temperature at which oil ignites. Ensuring safety is their primary role. Each tool plays a unique part in testing.

Standards For Fuel Use

Clear standards guide the conversion of motor oil to fuel. These standards prevent engine damage and ensure safety. Specifications cover chemical composition and combustion properties. The flash point must align with fuel safety norms. Viscosity must match engine requirements. Clean oil should have minimal impurities. Meeting these standards protects both engines and users. Adhering strictly to guidelines is essential for successful fuel conversion.

Eco-friendly Disposal

Eco-friendly disposal of used motor oil is crucial for environmental preservation. Proper disposal prevents contamination of soil and water sources. Motor oil can be toxic if not handled correctly. Cleaning motor oil for fuel requires careful attention. It’s essential to ensure safe and responsible disposal methods are followed.

Safe Disposal Of Residuals

Residuals from oil cleaning must be disposed of safely. This ensures no harm comes to the environment. Use approved containers for oil waste. These containers prevent leaks and spills. Local waste facilities often accept oil waste. Check with them for specific disposal guidelines. Always avoid pouring oil on the ground or into drains.

Recycling Options

Recycling used motor oil is beneficial. It reduces environmental impact significantly. Many recycling centers accept motor oil. They refine and repurpose it for various uses. Some auto shops offer recycling services. They often accept used oil from customers. This process helps conserve natural resources. It also supports sustainable practices.

Legal Considerations

Understanding legal considerations is crucial in cleaning used motor oil for fuel. Follow regulations to ensure safe and compliant processes. Proper permits and disposal methods protect the environment and avoid legal issues.

Cleaning used motor oil for fuel is a process that can offer environmental benefits and cost savings. However, it’s crucial to understand the legal considerations involved in this practice. Navigating the legal landscape ensures you comply with laws and regulations, avoiding hefty fines or legal issues. Whether you’re an individual or a business, grasping these aspects is essential for a smooth and lawful operation.Regulations And Compliance

When considering cleaning used motor oil for fuel, understanding the regulations is key. Different countries and regions have specific laws governing the handling and recycling of used oil. For instance, the U.S. Environmental Protection Agency (EPA) regulates used oil under the Resource Conservation and Recovery Act (RCRA). In the UK, the Environment Agency oversees similar regulations. Make sure to check the local guidelines applicable in your area. Compliance isn’t just about following laws; it’s about ensuring safety and environmental protection. Using cleaned oil as fuel can be hazardous if not managed correctly. Consider the potential risks and ensure that your practices align with environmental safety standards.Permits Required

Before you begin, determine whether you need any permits. Most regions require permits for oil recycling operations. These permits ensure that your process doesn’t harm the environment or public health. For example, in some states in the U.S., you may need a permit from the state’s environmental agency. In the EU, the Waste Framework Directive may require you to obtain specific licenses. Getting the right permits can be a detailed process. Start by contacting your local environmental authority for guidance. They can provide you with the necessary forms and help clarify any requirements specific to your operation. Having the proper permits not only keeps you compliant but also builds trust with your community. People are more likely to support your endeavor if they know it’s legally and environmentally sound. Have you thought about how local regulations might impact your operation? Understanding these legal considerations can make or break your efforts in cleaning used motor oil for fuel.

Credit: m.wasteoiltodieseloil.com

Conclusion

Cleaning used motor oil for fuel offers practical benefits. It reduces waste and saves money. Following safe procedures is crucial. This helps protect the environment. It also ensures efficient fuel use. Start with basic equipment. Then, advance as you gain experience.

Regular checks maintain quality and safety. Experiment and learn from each process. Share tips with others interested in recycling. Knowledge sharing helps improve methods. Enjoy the satisfaction of responsible resource use. Use these steps to contribute positively. Sustainable practices make a difference.

Every small effort counts.