Imagine turning your used motor oil into diesel fuel. You could save money and reduce waste at the same time.

Sounds intriguing, right? This process is not only possible but also a practical solution for those looking to make the most of their resources. By learning how to convert used motor oil into diesel fuel, you can contribute to environmental sustainability while keeping your wallet happy.

You’ll discover the simple steps to transform your used oil into valuable diesel fuel, all from the comfort of your home. Get ready to explore this fascinating process and unlock its potential benefits for you and the planet.

Credit: www.youtube.com

Materials And Tools Needed

Gather used motor oil, a refining system, and safety gear. Ensure you have containers, a filtration system, and heat sources. Basic tools include wrenches, screwdrivers, and funnels.

Transforming used motor oil into diesel fuel can be an exciting and rewarding project. It’s a sustainable practice that not only saves money but also helps the environment. Before you dive into the process, it’s crucial to gather the right materials and tools. This ensures safety and efficiency, paving the way for a successful operation.Materials Needed

To start, you’ll need a collection of specific materials. First up, gather used motor oil. Ensure it’s free of contaminants like water or coolant. This is crucial for the refining process. You’ll also need a catalyst, typically available at chemical supply stores. It’s the magic ingredient that helps break down the oil into usable fuel. Next, a diesel fuel additive is important. This enhances the quality and performance of your end product. Don’t forget a filtering system, like a simple mesh or a more sophisticated centrifuge, to separate impurities from the oil. Lastly, have a clean container ready to store your refined diesel fuel.Tools Needed

Equipping yourself with the right tools is equally important. A reliable distillation unit is essential. This is where the transformation happens, converting oil into diesel. You might be surprised to find that a simple, homemade setup can be effective. However, ensure it’s safely constructed to handle high temperatures. Safety gear is non-negotiable. Have gloves, goggles, and protective clothing. These safeguard you against accidental spills and splashes. Additionally, a thermometer helps monitor temperatures during the process. Temperature control is key to achieving high-quality diesel fuel.Setting Up Your Workspace

Creating a safe workspace is vital. Choose a well-ventilated area away from any flammable materials. This reduces the risk of accidents. Organize your tools and materials within easy reach. This keeps the process smooth and minimizes disruptions. Think about space management. Do you have enough room to operate safely? Ensure your workspace is clutter-free. A neat setup enhances focus and efficiency. It’s surprising how much a little organization can boost your productivity.Considerations For Safety

Safety should be your top priority. Are you wearing the right gear? Make sure your protective clothing is intact. Double-check your equipment for leaks or defects. This prevents mishaps during the process. Regularly inspect your distillation unit. It should be in perfect working condition. This not only ensures safety but also guarantees the quality of your diesel fuel. Finally, have a fire extinguisher nearby. It’s a precautionary measure that gives peace of mind. Embarking on this project is a journey of learning and discovery. With the right materials and tools, you’re well on your way to making diesel fuel from used motor oil. Are you ready to take on this eco-friendly challenge?Safety Precautions

Transforming used motor oil into diesel fuel requires careful handling. Safety precautions are essential to prevent accidents. Working with chemicals and heat can be risky. Ensuring safety measures can protect you and the environment. This section focuses on crucial safety steps.

Wear Protective Gear

Always wear protective gloves and goggles. They shield against chemical splashes. Use a lab coat or apron to cover your clothing. Sturdy footwear prevents injuries from spills.

Ensure Proper Ventilation

Work in a well-ventilated area. Toxic fumes can build up quickly. Open windows and use fans. This ensures a continuous flow of fresh air.

Use Fire-resistant Equipment

Choose fire-resistant containers and tools. Heat is involved in the conversion process. Fire-resistant materials reduce the risk of combustion. Always have a fire extinguisher nearby.

Keep A First Aid Kit Ready

Accidents can happen anytime. A first aid kit should be within reach. Equip it with necessary supplies. This ensures immediate response to injuries.

Conduct Regular Safety Checks

Inspect equipment regularly for wear and tear. Faulty equipment can lead to accidents. Regular checks ensure everything is in working order.

Follow Instructions Precisely

Stick to the process instructions. Any deviation can cause hazards. Precise adherence ensures safety and success.

Collecting Used Motor Oil

Turning used motor oil into diesel fuel is a practical skill. It reduces waste and saves money. The first step in this process is collecting used motor oil. Doing it right ensures a smooth conversion later.

Understanding Sources

Used motor oil comes from many sources. Cars, trucks, and machinery produce it. Auto repair shops are a great place to find it. They often have large quantities available.

Setting Up Collection Points

Collection points make gathering oil easier. Ask local garages to set aside oil for you. They might be happy to help. Offer to take it off their hands regularly.

Ensuring Proper Storage

Storing used motor oil properly is crucial. Use sturdy containers with tight lids. Store them away from sunlight. This prevents contamination and makes processing easier.

Safety Measures

Handling used motor oil requires safety measures. Wear gloves to protect your skin. Avoid direct contact. Make sure your collection area is well-ventilated.

Quality Check

Check the quality of the oil before collecting. Avoid oil with water or dirt. Clean oil is easier to convert into diesel fuel. Inspect containers for leaks.

Building Relationships

Develop relationships with oil suppliers. Trust and cooperation lead to better access. They might notify you when they have oil available. This keeps your supply steady.

Filtering The Oil

Filtering the oil is a key step in making diesel fuel from used motor oil. This process removes impurities and contaminants. Clean oil ensures smooth conversion to diesel. Proper filtration can significantly improve the quality of the final product. Let’s explore the essential steps of oil filtration.

Initial Filtration

Start by pouring the used motor oil through a metal strainer. This removes large particles and debris. Use a funnel to guide the oil smoothly. Next, use a coffee filter or cheesecloth. This catches smaller particles. Repeat this process for better results. Initial filtration prepares the oil for advanced steps.

Advanced Filtration Techniques

After initial filtering, use a centrifuge. It separates fine particles. Spin the oil at high speeds. This method is effective in removing micro-impurities. Another technique involves using a filter press. It pushes oil through fine filters. These filters trap remaining impurities. Both techniques enhance oil purity. Clean oil leads to better diesel production.

Heating And Distillation Process

The heating and distillation process is key to converting used motor oil into diesel fuel. This method separates impurities and extracts valuable hydrocarbons. By following a structured approach, you can achieve a cleaner, usable fuel.

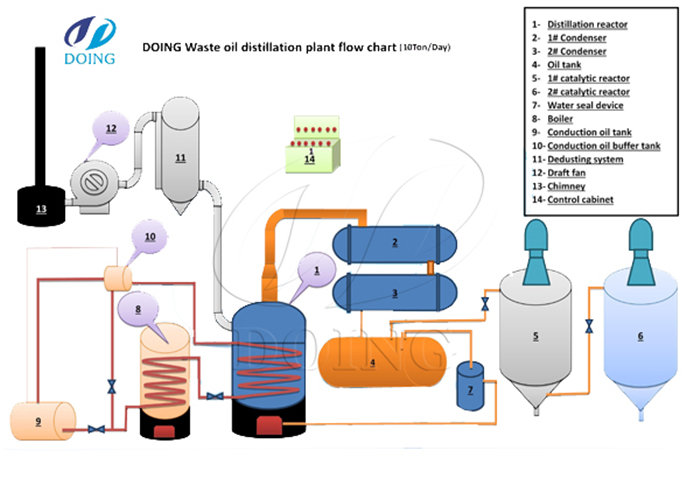

Setting Up The Distillation Unit

First, select a safe, well-ventilated area. This ensures safety during the process. Set up your distillation unit on a stable surface. A heat-resistant container works best for holding the oil. Attach a condenser to the container for efficient vapor collection. Secure all connections to prevent leaks.

Next, check the unit for any faults. This prevents accidents and ensures smooth operation. Place a thermometer in the container. This will help in monitoring the temperature accurately. Ensure the condenser leads to a collection vessel for the diesel.

Monitoring Temperature

Begin by heating the oil gently. Use a controlled heat source. Monitor the temperature with precision. Maintaining a consistent temperature is crucial. Aim for 370°C to 400°C. This range helps in breaking down the oil efficiently.

Watch the thermometer closely. Sudden spikes can lead to issues. Adjust the heat source as needed. Consistent monitoring ensures quality diesel output. Collect the distilled diesel in a clean container. Allow it to cool before storage or use.

Condensing Diesel Fuel

Condensing diesel fuel from used motor oil is a fascinating process that combines science with sustainability. This step is crucial in transforming waste oil into valuable diesel, making it a practical choice for eco-conscious individuals. If you’ve ever wondered about the magic behind converting black, greasy motor oil into clean-burning diesel, you’re about to find out.

Using A Condenser

A condenser plays an essential role in this transformation. Its main job is to cool down the vaporized oil, turning it back into liquid form. Think of it as the bridge between the oily fumes and the fresh diesel you collect.

Setting up a condenser isn’t as daunting as it sounds. You can use a simple water-cooled condenser, often found in DIY distillation kits. Ensure it’s tightly connected to avoid leaks, which can waste product and create safety hazards.

Have you ever tried building a science project at home? This is somewhat similar. The satisfaction you get from seeing the clear liquid drip out, knowing it’s your own creation, is unparalleled. Plus, it’s a great way to understand the science behind the fuel you use every day.

Collecting The Diesel

After the vapor cools, it turns into liquid diesel, ready for collection. Make sure to use a clean container to catch the diesel. This ensures that your final product is free from contaminants.

Labeling the container is a small yet critical step. It avoids confusion and helps in tracking the amount of diesel produced. You might wonder why this matters; it’s simply good practice and keeps your workspace organized.

As you watch the diesel collect, it’s hard not to feel a sense of accomplishment. You’ve taken something that would otherwise be discarded and turned it into usable energy. Isn’t that a testament to the power of human ingenuity?

So, are you ready to give it a try? Remember, safety first. Always work in a well-ventilated area and wear protective gear. After all, the real reward is not just the diesel, but the knowledge and skills you gain along the way.

Testing Diesel Quality

Transforming used motor oil into diesel fuel involves a careful refining process. This technique can help reduce waste and produce usable diesel. Testing diesel quality ensures safety and efficiency in engines.

Turning used motor oil into diesel fuel can be a rewarding process, but ensuring the quality of your diesel is crucial. Testing diesel quality involves checking various properties to make sure the fuel is safe and efficient to use. Whether you’re a hobbyist or looking to save some money, understanding how to test your diesel can make a significant difference in your results.Checking Fuel Properties

When checking the fuel properties, focus on key aspects such as viscosity, density, and flash point. Viscosity affects how the diesel flows in your engine, impacting performance. You can use a simple viscometer to measure this property and compare it to standard diesel values. Density is another critical property. A hydrometer can help you determine if your homemade diesel is within acceptable density ranges. This ensures that the energy content of your fuel is similar to commercial diesel. Flash point testing is essential for safety. A higher flash point indicates a lower risk of ignition, making your diesel safer to handle and store. You can use a flash point tester to check if your diesel meets safety standards.Ensuring Purity

Purity is vital for preventing engine damage. Impurities like water, metals, or sludge can harm your engine over time. Using a centrifuge can help remove water and particulates effectively. Consider using a filter system to catch remaining impurities. A good filter setup can prevent small particles from entering your engine, ensuring smoother operation. You might wonder how often you should test your diesel. Regular testing, especially after each batch, helps maintain consistent quality. How confident are you about the purity of your homemade diesel? Taking the time to test could save you from costly repairs and improve performance. By checking these properties and ensuring purity, you can confidently use your homemade diesel fuel. Understanding and testing diesel quality not only ensures safety but also enhances your fuel’s performance.

Credit: m.wasteoiltodieseloil.com

Storage And Handling

Handling and storing used motor oil is crucial in making diesel fuel. Proper storage and careful handling ensure safety and efficiency. They protect the environment from potential hazards. Here’s a guide to storing and handling used motor oil effectively.

Proper Storage Techniques

Store used motor oil in a cool, dry place. Use containers made of metal or plastic. Ensure they are free from leaks. Label each container clearly. Mark the date and type of oil. This helps keep track of your stock.

Keep containers tightly sealed. Prevent air and moisture from entering. Both can cause contamination. Check for signs of rust or damage. Replace faulty containers immediately. This avoids spills and leaks.

Handling Safety

Wear protective gear when handling used motor oil. Gloves, goggles, and aprons are essential. They protect your skin and eyes. Avoid direct contact with the oil.

Use funnels and spouts to pour oil. This reduces spills and splashes. Clean spills immediately with absorbent materials. Never use water for cleaning oil spills. It can spread the oil further.

Keep the area well-ventilated. Fumes from used motor oil can be harmful. Ensure there is no smoking or open flames nearby. Used motor oil is flammable. Be cautious to prevent accidents.

Environmental Considerations

Creating diesel fuel from used motor oil involves various environmental considerations. This process offers potential benefits but also comes with challenges. Understanding these can help minimize harm to our planet. Ensuring a cleaner process is crucial for sustainable practice.

Minimizing Pollution

Pollution during the conversion process is a major concern. Proper equipment reduces harmful emissions. Ensure systems are regularly maintained. This keeps them efficient and less polluting. Use filters to trap harmful particles. This helps in maintaining cleaner air quality. Regular checks ensure all systems operate smoothly.

Disposal Of Byproducts

Byproducts are inevitable in fuel production. Safe disposal is essential to avoid environmental harm. Some byproducts can be recycled or reused. This reduces waste and conserves resources. Always follow local regulations for disposal. This ensures safe and responsible handling. Seek professional advice for complex byproduct management.

Credit: www.purepathtech.com

Conclusion

Making diesel fuel from used motor oil offers great benefits. It helps recycle waste and reduce environmental impact. This process can save money and resources. Remember to follow all safety guidelines carefully. Use the right equipment and methods. Proper handling ensures efficiency and safety.

This method can be a sustainable choice for many. It’s important to keep learning and improving techniques. Stay informed about regulations and innovations in this field. With patience and care, converting used oil to diesel can be rewarding. Embrace this eco-friendly approach for a better future.