Maintaining a properly functioning brake system is essential for safe driving. However, over time, brake lines can become damaged or corroded, leading to a decrease in braking performance. If you find yourself with a broken brake line, it’s crucial to address the issue promptly.

In this guide, we’ll explore the steps involved in repairing a broken brake line. By following these instructions, you can restore your brake system’s integrity and ensure reliable stopping power when you need it most.

So, let’s dive in and learn how to tackle this repair efficiently and effectively.

Credit: www.brakeandfrontend.com

How To Repair Brake Line With Compression Fitting

To repair a broken brake line with a compression fitting, Just follow the steps below and you’ll be back on the road in no time.

Tools And Materials You’ll Need:

- Brake line: Ensure you have the correct length and diameter for your specific vehicle.

- Compression fitting: Opt for a fitting that matches the diameter of your brake line.

- Tube cutter: Used to cut the brake line to the desired length.

- Flare nut wrench: Necessary for securely tightening the compression fitting.

- Brake line flaring tool: Required for creating a flare on the brake line.

- Safety glasses and gloves: Safety precautions are essential when working with brake lines and automotive fluids.

Steps To Repair Brake Line With Compression Fitting:

- Prepare your workspace and vehicle: Park your vehicle on a level surface and engage the parking brake. Place wheel chocks behind the rear wheels for added safety. Wear safety glasses and gloves to protect yourself during the repair process.

- Locate the damaged brake line: Identify the section of the brake line that needs to be repaired. Thoroughly inspect the line for any cracks, leaks, or other signs of damage. Mark the section to be replaced with a marker or tape.

- Prepare the new brake line: Measure and cut the replacement brake line to the desired length using a tube cutter. Ensure the cut is clean and straight to ensure a proper fit.

- Create a flare on the brake line: Use a brake line flaring tool to create a double flare on one end of the new brake line. This flare will provide a secure connection when fitting it with the compression fitting.

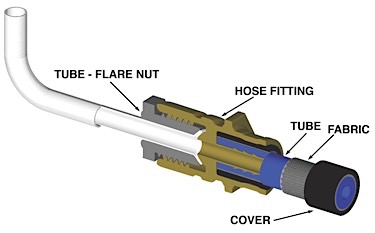

- Prepare the compression fitting: Remove the nut and sleeve from the compression fitting. Insert the sleeve onto the brake line, followed by the nut. Ensure they are facing the correct direction for installation.

- Connect the brake line and compression fitting: Insert the flared end of the brake line into the compression fitting until it reaches the collar. Finger tighten the nut onto the fitting.

- Tighten the compression fitting: Use a flare nut wrench to securely tighten the compression fitting onto the brake line. Make sure it is tight enough to prevent any leaks but avoid over-tightening, as it may damage the fitting or brake line.

- Test for leaks: Once the fitting is tightened, carefully inspect the repair area for any signs of leaks. It’s crucial to ensure there are no leaks before moving on.

- Bleed the brake system: After confirming that there are no leaks, bleed the brake system to remove any air trapped in the brake lines. Properly bleeding the brakes will ensure optimal brake performance.

- Test the brakes: Finally, test the brakes by pumping them a few times and applying pressure to ensure they’re functioning correctly. Take your vehicle for a short test drive to be certain that the repair was successful.

Remember, safety should always be your top priority when working on any automotive repair. If you’re unsure or uncomfortable performing brake line repairs yourself, it’s best to consult a professional mechanic.

With patience and care, you can successfully repair a broken brake line using a compression fitting and get back on the road safely.

How To Fix Brake Lines With Compression Fittings

To fix brake lines with compression fittings, follow these steps:

1. Start by locating the damaged section of the brake line and cutting it out.

2. Insert the compression fittings onto each end of the remaining brake line and tighten them securely.

3. Finally, use a tube bender to shape the repaired brake line as needed.

If you’ve discovered a broken brake line in your vehicle, it’s crucial to address the issue promptly to ensure your safety on the road. Repairing a broken brake line may seem like a daunting task, but with the right tools and knowledge, you can fix it yourself.

One method for repairing brake lines is by using compression fittings, which provide a secure and leak-free connection. In this section, we will guide you through the step-by-step process of fixing brake lines with compression fittings.

Materials Needed:

- Compression fittings (appropriately sized for your brake lines)

- Tubing cutter

- Flaring tool

- Wrenches (size may vary)

- Brake fluid

- Safety goggles

- Gloves

Step 1: Prepare The Brake Line

Before starting the repair process, it’s essential to prepare the brake line for the compression fitting installation:

- Locate the section of the brake line that needs repair.

- Use a tubing cutter to cut the damaged section of the brake line. Ensure that the cut is clean and square.

Step 2: Flare The Brake Line

Flaring the ends of the brake line will allow the compression fittings to securely attach:

- Select the appropriate size on your flaring tool to match the brake line diameter.

- Insert the brake line into the flaring tool until it seats against the flaring block.

- Tighten the flaring tool to create a double or bubble flare at the end of the brake line. Refer to your specific flaring tool instructions for guidance.

Step 3: Install The Compression Fittings

Now that you have prepared the brake line, it’s time to install the compression fittings:

- Slide a compression nut onto the brake line, followed by the compression sleeve.

- Insert the flared end of the brake line into the compression fitting body.

- Thread the compression nut onto the fitting body, ensuring it is tight but not excessively so. Use wrenches for a secure connection.

Step 4: Check For Leaks And Bleed The Brake System

After installing the compression fittings, it’s crucial to check for any possible leaks and bleed the brake system:

- Inspect the connections for any signs of leakage, such as brake fluid seepage.

- If leaks are present, tighten the fittings accordingly.

- Bleed the brake system to remove any air bubbles and ensure proper brake operation. Refer to your vehicle’s manual for the correct bleeding procedure.

By following these steps, you can repair a broken brake line using compression fittings. However, it’s essential to note that if you’re unsure or uncomfortable with the repair process, it’s best to consult a professional mechanic to ensure a proper and safe repair.

Remember, properly functioning brake lines are crucial for your vehicle’s braking system, so it’s vital to address any issues promptly. Stay safe on the road!

Credit: m.youtube.com

Conclusion

Repairing a broken brake line is essential for maintaining the safety of your vehicle. By following the steps outlined in this post, you can successfully address this issue and ensure proper functionality of your brakes.

Remember, safety should always be a top priority when it comes to vehicle maintenance.

With proper care and attention to detail, you can keep your brakes in good working order for smoother and safer driving experiences.