How to Test Fuel Injectors With Multimeter – Step by Step Guide

Step 1: Locating The Fuel Injector

In order to test fuel injectors with a multimeter, the first step is to locate the fuel injector within the engine. This requires determining the type and location of the fuel injectors.

Different engines may have different types and locations, so it is important to consult the vehicle’s manual or perform a thorough online search for specific instructions.

Once you have identified the fuel injectors, the next step is to locate the injector wiring harness and connectors. These are usually located near the fuel injectors and can be identified by their unique design and connection points.

Carefully inspect the wiring harness to ensure it is in good condition and properly connected.

Step 2: Disconnecting The Fuel Injector

Before you begin, it is crucial to prioritize safety. Following proper precautions will prevent any accidents during the process. To safely remove the fuel injector connector, start by ensuring the engine is turned off and the ignition is disabled.

This will eliminate any potential risk of injury or damage. It is also recommended to wear protective gloves and eyewear.

Once you have taken the necessary safety measures, locate the fuel injector connector, which is typically found near the fuel rail. Gently press the connector’s release tab to unlock and separate it from the fuel injector. Be cautious not to force or break the connector during this step.

Remember, safety should always be the top priority during any automotive maintenance task. By following these precautions, you can safely and effectively disconnect the fuel injector connector.

Step 3: Testing The Injector Resistance

When testing the resistance of fuel injectors with a multimeter, it is important to set the multimeter to measure resistance. This step ensures accurate results and proper functionality.

To set the multimeter, begin by turning it on and selecting the resistance measurement setting. Most multimeters have multiple options for measuring resistance, such as ohms or kilohms.

Choose the appropriate setting based on the specifications of your multimeter. It is also essential to select the resistance range that best matches the expected resistance value of the fuel injectors.

This range can typically be adjusted using a dial or button on the multimeter. Once the multimeter is properly set, it is ready to be used for measuring the resistance of the fuel injectors.

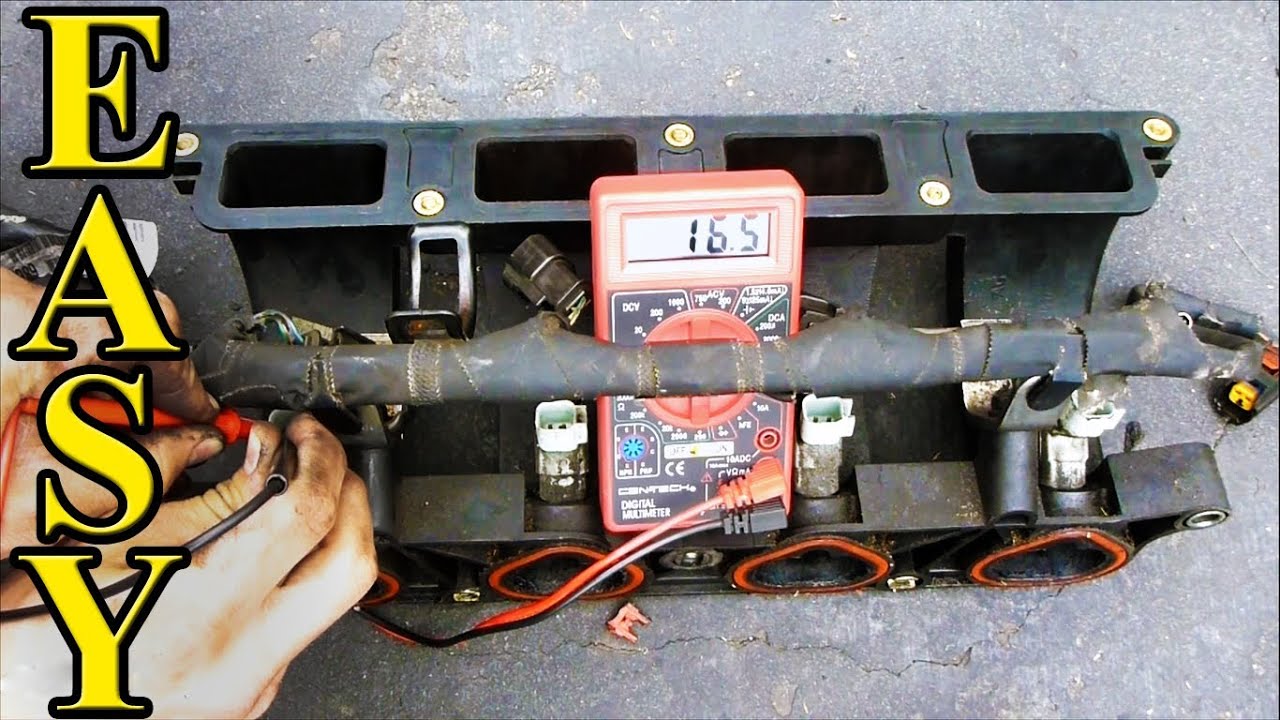

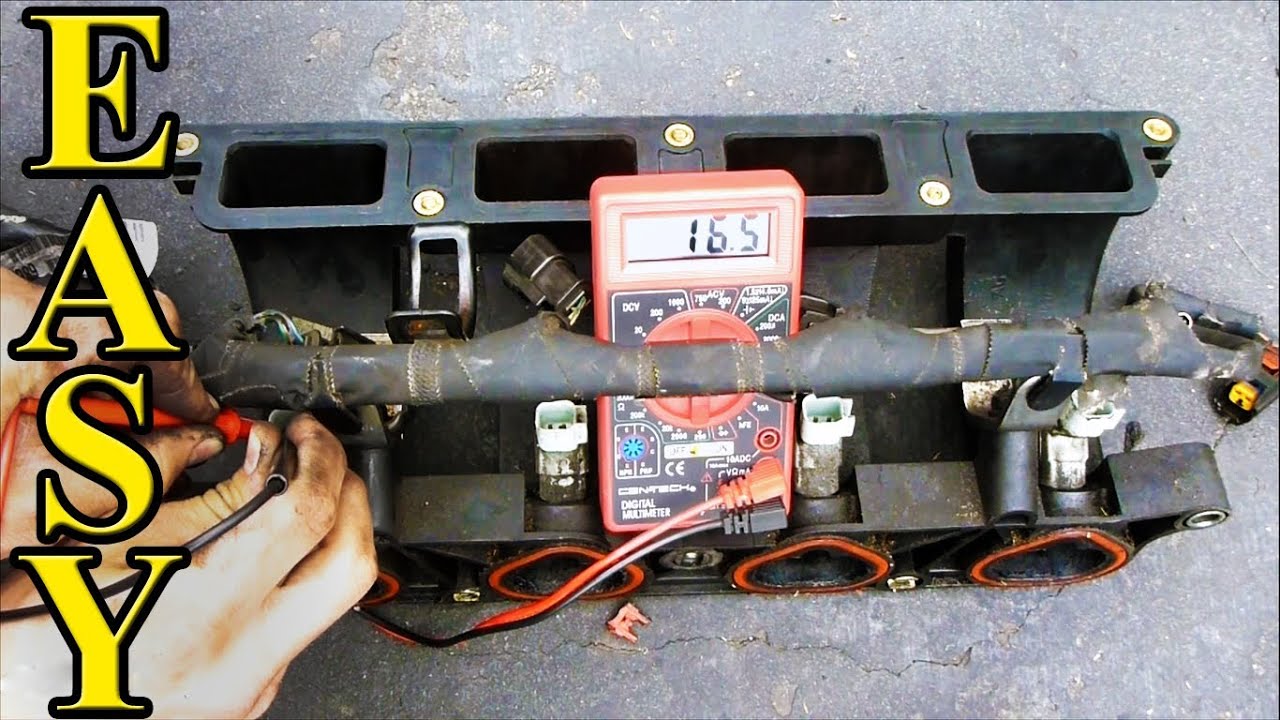

Credit: m.youtube.com

Step 4: Checking For Injector Continuity

Verifying the continuity of the fuel injector is an essential step in testing fuel injectors with a multimeter. To begin, connect the positive (+) lead of the multimeter to the injector’s terminal and the negative (-) lead to the fuel injector body.

With the multimeter set to the ohm (Ω) setting, check for a reading on the display. If the multimeter displays a reading of zero or very low resistance, it indicates that the injector has continuity, which means there is a proper electrical connection.

On the other hand, if the multimeter shows OL or very high resistance, it indicates no continuity, suggesting a broken or faulty injector.

| Multimeter Reading | Continuity Status |

|---|---|

| 0 or very low resistance | Injector has continuity |

| OL or very high resistance | No continuity, broken or faulty injector |

Step 5: Inspecting For Injector Leakage

In the process of testing fuel injectors with a multimeter, step 5 involves inspecting for injector leakage. This is an important part of the testing process as leakage can lead to a variety of issues with the fuel injection system.

When performing a leakage test on the fuel injector, it is crucial to interpret the results accurately and diagnose any potential issues that may arise.

Step 6: Repeating The Process For Other Fuel Injectors

Testing all the fuel injectors in the vehicle is an important step in the process of testing fuel injectors with a multimeter.

Once you have successfully tested one fuel injector (as outlined in the previous steps), it is necessary to repeat the process for the rest of the injectors. This ensures that all the injectors are functioning properly and providing an even distribution of fuel to the engine.

When testing each fuel injector, it is advisable to keep track of the results for comparison. This allows you to identify any inconsistencies or discrepancies between the injectors.

You can record the resistance values or voltage readings for each injector and compare them to determine if any injectors deviate significantly from the norm.

Diagnosing And Fixing Common Fuel Injector Problems

When it comes to diagnosing and fixing common fuel injector problems, using a multimeter is a valuable tool. Clogged or dirty injectors can lead to a decrease in fuel efficiency and engine performance.

To test for this issue, start by disconnecting the fuel injectors and using a multimeter to measure the resistance between the injector terminals. A reading that is significantly higher or lower than the manufacturer’s specifications indicates a clogged or dirty injector.

Faulty injector wiring is another common problem that can be diagnosed and fixed using a multimeter. Start by eliminating other potential causes, such as a faulty fuel pump or problematic fuel pressure regulator, before testing the injector wiring.

Use the multimeter to check the injector’s resistance and compare it to the specified values provided by the vehicle manufacturer. If the resistance is significantly higher or lower, it may indicate faulty injector wiring.

In addition, a malfunctioning injector driver circuit can also be identified by using a multimeter to check the voltage. Start by disconnecting the injector and probing the driver circuit with the multimeter. A voltage reading outside the specified range indicates a malfunctioning circuit.

Professional Fuel Injector Testing Services

Professional fuel injector testing services are crucial for ensuring the efficient performance of your vehicle. These services provide a comprehensive assessment of your fuel injectors using advanced diagnostic tools such as multimeters.

If you are facing issues such as rough idling, decreased fuel efficiency, or engine misfires, it may be time to seek professional help.

Trained technicians can accurately diagnose and identify any problems with your fuel injectors, saving you time and money on unnecessary repairs. They have the expertise to test the injectors for clogs, leaks, or faulty electrical connections.

Once the issues are identified, they can provide specialized cleaning and maintenance services to restore optimal performance.

By opting for professional testing and cleaning services, you can benefit from improved fuel efficiency, smoother engine performance, and reduced emissions.

Regular maintenance of your fuel injectors can prevent costly repairs and breakdowns in the long run. Don’t wait for your engine to show signs of trouble, consult a professional for fuel injector testing today.

Conclusion

To sum up, testing fuel injectors with a multimeter is a simple and effective way to diagnose any issues with your vehicle’s fuel system.

By following the step-by-step process outlined in this blog post, you can determine whether your injectors are functioning properly or if they need to be replaced.

Regularly checking and maintaining your fuel injectors will ensure optimal engine performance, fuel efficiency, and overall reliability.

Don’t forget to consult your vehicle’s manual for specific instructions. Happy testing!

Testing your fuel injectors using a multimeter can help you determine if they are working properly or need to be replaced. By measuring the resistance and continuity, you can assess the overall performance of the injectors, ensuring your vehicle runs smoothly and efficiently.

We will guide you through the step-by-step process of testing fuel injectors with a multimeter. So, let’s get started and diagnose your fuel injector issues today!

Why Regular Fuel Injector Testing Is Necessary

Regular fuel injector testing is necessary to ensure optimal engine performance. By testing the fuel injectors, you can identify any issues or malfunctions that may be causing poor fuel efficiency or power loss.

This allows you to prevent fuel wastage and ensure that your engine is running at its best. Testing fuel injectors also helps in extending the lifespan of the fuel injectors. By catching any problems early on, you can address them promptly and prevent further damage to the injectors.

It is recommended to test fuel injectors with a multimeter, as this device accurately measures electrical resistance and can help identify any issues with the injectors. Regular testing of fuel injectors with a multimeter is a simple and effective way to ensure that your engine operates smoothly and efficiently.

Overview Of Fuel Injector Testing Methods

Testing fuel injectors is an essential part of automotive diagnostics. There are various methods used in the industry to determine the performance and efficiency of fuel injectors. These methods include:

| Method | Advantages | Disadvantages |

|---|---|---|

| Resistance Testing | Simple and quick | Does not provide detailed information on injector performance |

| Flow Testing | Accurately measures fuel delivery | Requires specialized equipment |

| Leak Testing | Detects fuel leaks and injector seal issues | Does not assess the injector spray pattern |

| Pulse Testing | Assesses injector response time | Does not provide information on fuel flow |

Each testing method has its advantages and disadvantages.

Resistance testing is quick and easy, but it may not provide detailed information on injector performance.

Flow testing accurately measures fuel delivery, but it requires specialized equipment.

Leak testing can detect fuel leaks and seal issues but does not assess injector spray patterns.

Pulse testing assesses the response time of injectors but does not provide information on fuel flow.

It is important to consider the specific requirements of the diagnostics you are performing when choosing a fuel injector testing method. Understanding the advantages and disadvantages of each method can help you make an informed decision.

Gathering The Required Tools And Materials

To test fuel injectors with a multimeter, you will need a few essential tools and materials:

| Multimeter |

| Safety goggles and gloves |

| Injector testing kit (optional) |

A multimeter is the key tool you’ll need for this fuel injector testing process. It enables you to measure electrical resistance, voltage, and other important parameters.

Make sure to invest in quality safety goggles and gloves to protect yourself during the testing procedure. While not mandatory, an injector testing kit can provide additional convenience and accurate results.

Having these tools and materials at your disposal will help ensure a smooth and efficient fuel injector testing process.

Preparing The Vehicle And Multimeter

Ensuring the engine is cool and the vehicle is parked in a safe area: Before testing the fuel injectors, it is essential to ensure that the engine has cooled down to a safe temperature.

Additionally, park the vehicle in a well-ventilated and secure area to prevent any accidents or mishaps during the testing process.

Understanding the multimeter functions and settings: Familiarize yourself with the various functions and settings of the multimeter that you will be using for injector testing. Ensure you have the necessary knowledge about the different symbols, dials, and buttons on the multimeter to accurately perform the test.

Setting up the multimeter for injector testing: Set the multimeter to the appropriate setting for fuel injector testing. This will typically involve selecting the “ohms” function on the multimeter and adjusting the dial or buttons to the correct resistance range.

Consult the multimeter’s user manual or online resources for specific instructions based on your multimeter model.

Testing the fuel injectors: Once the vehicle is prepared, and the multimeter is set up correctly, you can proceed with testing the fuel injectors. Follow the recommended procedures and carefully monitor the readings on the multimeter display for each injector.

Document the readings and compare them to the manufacturer’s specifications to determine if any injectors are faulty or require further attention.

How to Test Fuel Injectors With Multimeter – Step by Step Guide

Step 1: Locating The Fuel Injector

In order to test fuel injectors with a multimeter, the first step is to locate the fuel injector within the engine. This requires determining the type and location of the fuel injectors.

Different engines may have different types and locations, so it is important to consult the vehicle’s manual or perform a thorough online search for specific instructions.

Once you have identified the fuel injectors, the next step is to locate the injector wiring harness and connectors. These are usually located near the fuel injectors and can be identified by their unique design and connection points.

Carefully inspect the wiring harness to ensure it is in good condition and properly connected.

Step 2: Disconnecting The Fuel Injector

Before you begin, it is crucial to prioritize safety. Following proper precautions will prevent any accidents during the process. To safely remove the fuel injector connector, start by ensuring the engine is turned off and the ignition is disabled.

This will eliminate any potential risk of injury or damage. It is also recommended to wear protective gloves and eyewear.

Once you have taken the necessary safety measures, locate the fuel injector connector, which is typically found near the fuel rail. Gently press the connector’s release tab to unlock and separate it from the fuel injector. Be cautious not to force or break the connector during this step.

Remember, safety should always be the top priority during any automotive maintenance task. By following these precautions, you can safely and effectively disconnect the fuel injector connector.

Step 3: Testing The Injector Resistance

When testing the resistance of fuel injectors with a multimeter, it is important to set the multimeter to measure resistance. This step ensures accurate results and proper functionality.

To set the multimeter, begin by turning it on and selecting the resistance measurement setting. Most multimeters have multiple options for measuring resistance, such as ohms or kilohms.

Choose the appropriate setting based on the specifications of your multimeter. It is also essential to select the resistance range that best matches the expected resistance value of the fuel injectors.

This range can typically be adjusted using a dial or button on the multimeter. Once the multimeter is properly set, it is ready to be used for measuring the resistance of the fuel injectors.

Credit: m.youtube.com

Step 4: Checking For Injector Continuity

Verifying the continuity of the fuel injector is an essential step in testing fuel injectors with a multimeter. To begin, connect the positive (+) lead of the multimeter to the injector’s terminal and the negative (-) lead to the fuel injector body.

With the multimeter set to the ohm (Ω) setting, check for a reading on the display. If the multimeter displays a reading of zero or very low resistance, it indicates that the injector has continuity, which means there is a proper electrical connection.

On the other hand, if the multimeter shows OL or very high resistance, it indicates no continuity, suggesting a broken or faulty injector.

| Multimeter Reading | Continuity Status |

|---|---|

| 0 or very low resistance | Injector has continuity |

| OL or very high resistance | No continuity, broken or faulty injector |

Step 5: Inspecting For Injector Leakage

In the process of testing fuel injectors with a multimeter, step 5 involves inspecting for injector leakage. This is an important part of the testing process as leakage can lead to a variety of issues with the fuel injection system.

When performing a leakage test on the fuel injector, it is crucial to interpret the results accurately and diagnose any potential issues that may arise.

Step 6: Repeating The Process For Other Fuel Injectors

Testing all the fuel injectors in the vehicle is an important step in the process of testing fuel injectors with a multimeter.

Once you have successfully tested one fuel injector (as outlined in the previous steps), it is necessary to repeat the process for the rest of the injectors. This ensures that all the injectors are functioning properly and providing an even distribution of fuel to the engine.

When testing each fuel injector, it is advisable to keep track of the results for comparison. This allows you to identify any inconsistencies or discrepancies between the injectors.

You can record the resistance values or voltage readings for each injector and compare them to determine if any injectors deviate significantly from the norm.

Diagnosing And Fixing Common Fuel Injector Problems

When it comes to diagnosing and fixing common fuel injector problems, using a multimeter is a valuable tool. Clogged or dirty injectors can lead to a decrease in fuel efficiency and engine performance.

To test for this issue, start by disconnecting the fuel injectors and using a multimeter to measure the resistance between the injector terminals. A reading that is significantly higher or lower than the manufacturer’s specifications indicates a clogged or dirty injector.

Faulty injector wiring is another common problem that can be diagnosed and fixed using a multimeter. Start by eliminating other potential causes, such as a faulty fuel pump or problematic fuel pressure regulator, before testing the injector wiring.

Use the multimeter to check the injector’s resistance and compare it to the specified values provided by the vehicle manufacturer. If the resistance is significantly higher or lower, it may indicate faulty injector wiring.

In addition, a malfunctioning injector driver circuit can also be identified by using a multimeter to check the voltage. Start by disconnecting the injector and probing the driver circuit with the multimeter. A voltage reading outside the specified range indicates a malfunctioning circuit.

Professional Fuel Injector Testing Services

Professional fuel injector testing services are crucial for ensuring the efficient performance of your vehicle. These services provide a comprehensive assessment of your fuel injectors using advanced diagnostic tools such as multimeters.

If you are facing issues such as rough idling, decreased fuel efficiency, or engine misfires, it may be time to seek professional help.

Trained technicians can accurately diagnose and identify any problems with your fuel injectors, saving you time and money on unnecessary repairs. They have the expertise to test the injectors for clogs, leaks, or faulty electrical connections.

Once the issues are identified, they can provide specialized cleaning and maintenance services to restore optimal performance.

By opting for professional testing and cleaning services, you can benefit from improved fuel efficiency, smoother engine performance, and reduced emissions.

Regular maintenance of your fuel injectors can prevent costly repairs and breakdowns in the long run. Don’t wait for your engine to show signs of trouble, consult a professional for fuel injector testing today.

Conclusion

To sum up, testing fuel injectors with a multimeter is a simple and effective way to diagnose any issues with your vehicle’s fuel system.

By following the step-by-step process outlined in this blog post, you can determine whether your injectors are functioning properly or if they need to be replaced.

Regularly checking and maintaining your fuel injectors will ensure optimal engine performance, fuel efficiency, and overall reliability.

Don’t forget to consult your vehicle’s manual for specific instructions. Happy testing!