Imagine you’re driving down the road, and suddenly your car starts to sputter. You’ve checked the usual suspects—gas, oil, and battery—but everything seems in order.

What could it be? If you’ve ever found yourself in this predicament, the fuel pump driver module might be the culprit. This small but essential component ensures the smooth delivery of fuel to your engine, and when it fails, your car can grind to a halt.

By learning how to test the fuel pump driver module, you can save yourself time and money, and avoid the headache of a surprise breakdown. You’ll discover simple, effective methods to diagnose issues with your fuel pump driver module, empowering you to tackle car troubles with confidence. Don’t let a malfunctioning module keep you off the road—read on to learn how to keep your ride running smoothly.

Credit: www.f150forum.com

Basics Of Fuel Pump Driver Module

Testing the fuel pump driver module ensures your vehicle runs smoothly. Begin by checking for error codes with a diagnostic tool. Listen for unusual sounds from the fuel pump, and measure voltage and resistance using a multimeter.

Function And Importance

The fuel pump driver modulecontrols the fuel pump’s power. It ensures the pump delivers the right amount of fuel. This module plays a vital role in vehicle performance. Without it, the engine may not get enough fuel. This leads to poor performance or even a stall. The module helps maintain fuel pressure. This keeps the engine running smoothly.

Common Symptoms Of Malfunction

Malfunctioning fuel pump driver modules cause various symptoms. Engine stallingis common. Sometimes, the engine won’t start at all. You may notice poor acceleration. The vehicle might struggle to climb hills. Another sign is rough idling. Listen for unusual noises from the fuel tank. These noises may indicate issues. Fuel efficiency can also drop. This leads to increased fuel consumption. Addressing these symptoms promptly is crucial.

Credit: www.f150forum.com

Tools And Equipment Needed

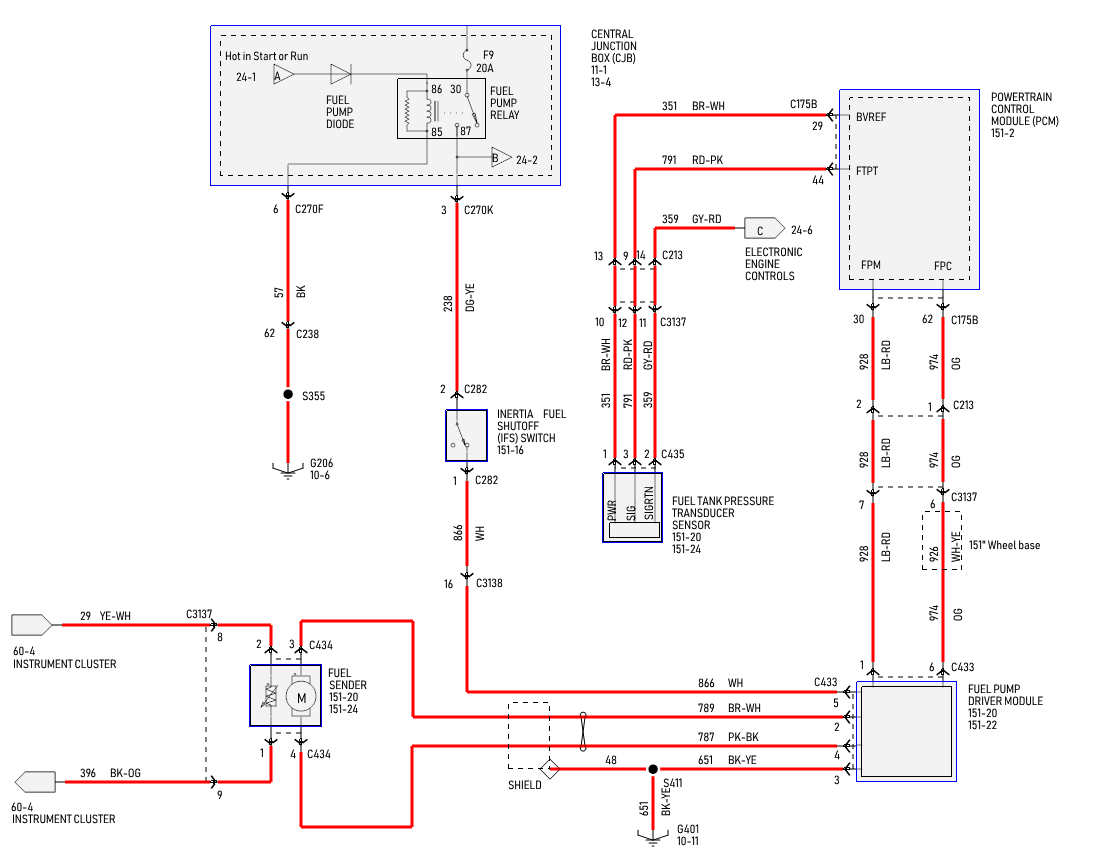

A multimeter is vital. It measures voltage and resistance. A fuel pressure gauge helps check pressure levels. Use a scan tool to read error codes. It identifies problems quickly. Wiring diagrams are helpful. They guide you through connections. Keep basic hand tools handy. Screwdrivers and wrenches are necessary.

Always wear safety goggles. Protect your eyes. Use gloves to keep hands safe. Ensure the engine is cool before starting. Disconnect the battery. It prevents shocks. Work in a well-ventilated area. Avoid fumes. Keep a fire extinguisher nearby. Safety first. Never smoke around fuel systems.

Initial Checks And Preparations

Start by checking for any visible damageor wear on the fuel pump driver module. Look for signs of corrosionor loose connections. Ensure all wiresare secure and not frayed. A quick look can tell a lot. It’s important to find any obvious problemsearly. This saves time later.

Always ensure the battery is in good condition. A weak batterycan give false results. Use a multimeter to check the battery’s voltage. The voltage should be around 12 volts. If the voltage is low, charge the battery first. This ensures accurate testing. Proper power is crucial for correct readings.

Credit: www.f150forum.com

Testing Procedures

Multimeters check voltage and resistance. Connect the multimeter to the module. Look for correct voltage readings. If readings are off, the module may be bad. Use the ohm setting to check resistance. High resistance can mean trouble. Check connections for loose wires. These can cause problems too.

An oscilloscope shows wave patterns. Connect it to the module. Look at the waveform on the screen. A steady pattern means the module works well. If the pattern jumps, there might be an issue. Adjust the settings for better view. Make sure all connections are tight.

Use a scan tool to check for error codes. Plug the tool into the car’s system. The tool shows codes for problems. Look up the codes in the manual. A common code points to a faulty module. Clear the codes and test again. Repeat if necessary.

Interpreting Test Results

Test results can show faulty signalsin the fuel pump driver module. These signals often mean something is wrong. Look for weak or irregular signals. These might be a sign of a bad module. Signals should be clear and consistent. If not, there may be a problem. Compare signals to normal standards. This helps find errors.

Identifying Faulty Signals

Bad signals are often weak or unclear. They may cause the car to stall. Check signals with a testing tool. Look for any breaks or gaps. These might mean a faulty module. Signals should match the expected pattern. If they don’t, there might be an issue.

Assessing Module Performance

Module performance shows if the fuel pump works right. A working module gives strong and clear signals. Weak performance can lead to car problems. Test the module with a reliable tool. Compare the results with good standards. This helps find any faults. Make sure signals are steady and strong.

Common Issues And Solutions

Wires can break or get loose. This stops the module from working. Check each wire for cuts or tears. A broken wire needs fixing. Connections must be tight. Loose ones can cause problems. Clean any rusty parts. Rust can stop the flow of power.

Use a tester for wires. This helps find bad spots. Replace any bad wires. This helps the module work right. Fixing wires is easy. It keeps the car running.

Outdated software can cause issues. Check for updates often. Manufacturers give software updates. Download and install them. This keeps the module working well. Firmware updates are also important. They fix bugs and improve function.

Use a computer to update. Follow the steps given. Connect the module to the computer. Run the update program. Ensure all updates are installed. This helps avoid future problems.

Expert Tips For Accurate Testing

Testing the fuel pump driver module needs care. Avoiding common mistakes helps. Don’t disconnect the battery while testing. It can damage parts. Always check connections first. Loose wires can give wrong results. Use the right tools. A multimeter is helpful. Read the manual before starting. Follow the steps. This keeps you safe. Safety is important.

Use advanced techniques for better results. Check the voltage at the module. Compare it with the manual’s values. Look for changes in the voltage. This shows if there is a problem. Use a scope if you have one. It shows signals clearly. Understanding signals helps in finding issues. Keep notes of your tests. It helps in future checks.

Maintenance And Prevention

Testing the fuel pump driver module ensures vehicle reliability. Start by checking power supply and ground connections. Use a multimeter to measure voltage levels, confirming proper operation.

Regular Check-ups

Regular check-ups are very important. They help keep the fuel pump driver module working well. Checking it every few months is a good idea. Look for signs of wear and tear. Listen for strange noises. These can show problems. Fix small issues before they become big. This saves time and money. Always check the wires and connections. Make sure they are tight. Loose wires can cause problems. Keep the area clean and free from dirt. Dirt can damage the module. A clean module lasts longer. Regular check-ups help prevent problems.

Preventive Measures

Taking steps to protect the fuel pump driver module is smart. Avoid driving with low fuel. This can damage the pump. Keep your gas tank at least half full. It helps the pump stay cool. Use good quality fuel. Bad fuel can harm the module. Change the fuel filter on time. A clean filter protects the pump. Check the battery often. A weak battery can cause the pump to work harder. Follow these steps to keep the module in good shape. Prevention saves money and keeps your car running smoothly.

Conclusion

Testing the fuel pump driver module is simple with clear steps. First, check the power supply. Next, examine the ground connections. Confirm the module’s output. These basic checks can prevent future issues. Regular inspections ensure your vehicle runs smoothly. Keep tools handy for quick fixes.

Stay alert to changes in performance. Early diagnosis saves money and time. Remember, safety comes first. Always work in well-ventilated areas. Following these tips helps maintain your vehicle. Understanding these steps builds your confidence in handling car repairs. Trust your instincts and consult a professional when needed.