Ball joints play a critical role in connecting the steering knuckle to the control arm, allowing for smooth and controlled movement of the wheels.

Over time, these joints can become loose due to wear and tear, leading to steering and suspension issues. We will discuss the importance of tightening ball joints and provide a step-by-step guide on how to accomplish this task.

Credit: www.moogparts.com

How Tight Should Ball Joints Be

When it comes to tightening a ball joint, it’s crucial to ensure the process is done correctly. Proper tightness is essential in maintaining the functionality and safety of the joint. Over tightening or under tightening can lead to premature wear and potential safety hazards.

To achieve the correct tightness, it’s important to refer to the manufacturer’s specifications for the specific ball joint being worked on. Utilizing a torque wrench can provide precise and accurate tightening, ensuring the ball joint is properly secured without being excessively tightened.

Regular inspection and maintenance of ball joints are also fundamental in prolonging their lifespan and ensuring optimal performance.

Can You Over Tighten Ball Joints

When it comes to tightening a ball joint, it’s essential to be mindful of not over-tightening it. Over-tightening can lead to excessive stress on the joint, potentially causing it to fail prematurely.

To avoid this, it’s important to follow the manufacturer’s recommended torque specifications and use a torque wrench to ensure proper tightness.

Additionally, regularly inspecting the ball joint for any signs of wear or damage can help prevent issues. Furthermore, it’s crucial to use the correct tools and techniques when tightening the ball joint to maintain its performance and longevity.

Overall, taking the time to tighten the ball joint properly can contribute to the overall safety and functionality of the vehicle.

How to Tighten a Ball Joint Properly

Tightening a ball joint is not a common maintenance procedure, as ball joints are typically replaced when they wear out or exhibit excessive play. However, if you are experiencing looseness in a ball joint and need a temporary fix, here are some general steps you can follow.

Keep in mind that this is not a recommended long-term solution, and replacing the ball joint is the best course of action for safety reasons.

-

Identify the Problem: Make sure that the looseness is indeed coming from the ball joint. Sometimes, other components in the suspension system may cause similar symptoms.

-

Inspect for Damage: Check the ball joint and surrounding components for visible damage. If the ball joint is damaged, it is crucial to replace it rather than attempting a temporary fix.

-

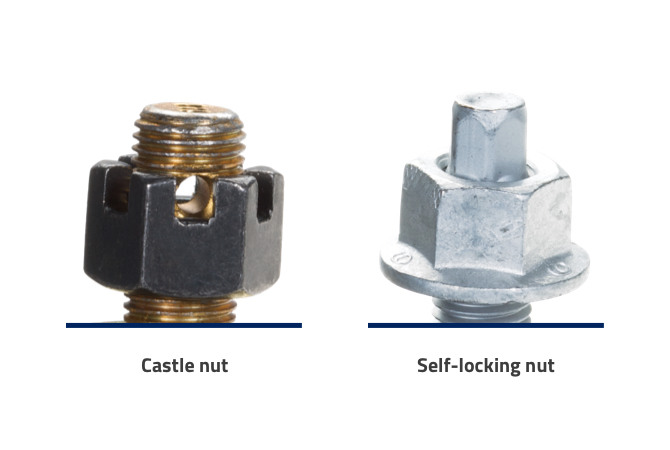

Tighten the Castle Nut: Ball joints typically have a castle nut that secures them to the control arm or steering knuckle. If the ball joint is adjustable, tightening this nut might reduce some play. Use the appropriate-sized socket and wrench to tighten the castle nut.

-

Check for a Grease Fitting: Some ball joints have grease fittings. If yours does, ensure it is properly lubricated. Lack of lubrication can lead to increased wear and looseness. Use a grease gun to add grease as needed.

-

Use a Locking Nut (If Applicable): Some ball joints have a locking nut that can be tightened against the adjusting nut to help prevent it from coming loose. If your ball joint has this feature, make sure it is properly adjusted and tightened.

-

Consult Vehicle Manual: Refer to your vehicle’s manual for specific instructions and torque specifications related to the ball joint. Over-tightening can lead to damage, so it’s essential to follow the manufacturer’s guidelines.

-

Temporary Fix Only: Keep in mind that tightening a ball joint is a temporary solution at best. If you notice any play or looseness in the joint, it’s strongly recommended to replace the ball joint as soon as possible to ensure safe operation of your vehicle.

Remember, if you are not comfortable or experienced with vehicle maintenance, it is advisable to seek professional help. Replacing or repairing suspension components is critical for your safety and the proper functioning of your vehicle.

How To Tighten Motorcycle Mirror Ball Joint

To tighten a motorcycle mirror ball joint, start by locating the ball joint on the mirror assembly and identify the locking mechanism.

Using the appropriate tools, carefully tighten the ball joint by adjusting the locking mechanism to secure the joint in place.

Ensure that the joint is tightened sufficiently to prevent any movement or vibration while riding. Test the tightness of the joint by moving the mirror to check for any play or wobbling.

If the joint is still loose, further adjustment may be necessary.

Regularly inspect the ball joint to maintain its tightness and ensure the safety and stability of the motorcycle mirror during use.

Conclusion

Tightening a ball joint is a simple task that can be done with careful attention to detail. By following the steps outlined in this guide, you can ensure the safety and stability of your vehicle’s suspension system.

Remember to regularly check and maintain your ball joints to prevent future issues.

Keep your car in top condition for a smoother ride.