Copper-nickel brake lines are DOT approved for automotive use. These lines meet rigorous safety standards set by the Department of Transportation.

Ensuring vehicle safety is paramount, and copper-nickel brake lines rise to the challenge with their DOT approval. Vehicle owners seek components that not only comply with safety regulations but also offer durability and reliability.

Copper-nickel alloys, known for their resistance to corrosion and high tensile strength, make for an excellent material in the harsh environment of brake systems.

For those upgrading or repairing their brake lines, choosing DOT-approved materials like copper-nickel can give peace of mind.

This resilient and flexible material stands up to the high-pressure demands of braking, while its approval by the DOT confirms its aptitude for maintaining safety on the road.

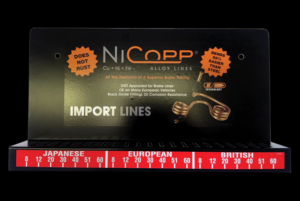

Credit: www.agscompany.com

Copper-nickel Brake Line Essentials

Copper-Nickel brake lines are crucial for any vehicle’s braking system. They’re admired for their ability to withstand harsh conditions.

Here’s what every car owner should know about them.

Characteristics Of Copper-nickel Alloy

- Corrosion Resistance: Stands strong against rust and decay.

- Durability: Maintains shape and function for years.

- Malleability: Bends easily without cracking or breaking.

- Low Magnetic Permeability: Doesn’t magnetize easily, adds safety.

Benefits In Brake System Applications

| Benefit | Impact |

|---|---|

| Longevity | Fewer replacements, saves money. |

| Safety | Reliable performance in severe weather. |

| Flexibility | Easy installation in complex systems. |

| Versatility | Suitable for most vehicles. |

Credit: www.agscompany.com

Dot Standards For Brake Lines

Ensuring your vehicle meets the Department of Transportation (DOT) standards for brake lines is crucial. These standards guarantee that the materials and construction of brake lines are safe for all road conditions.

They particularly emphasize durability and performance. So, when it comes to copper-nickel brake lines, the key question is: are they DOT approved?

Criteria For Dot Approval

The DOT sets specific criteria that all brake lines must meet to gain approval.

These criteria include:

- Construction Quality: Brake lines must be durable and able to withstand high pressures.

- Material Standards: Only materials resistant to corrosion and wear are acceptable.

- Performance: Brake lines should perform reliably under various temperatures and conditions.

- Burst Pressure: They must hold up against a minimum specified burst pressure.

- Compatibility: Brake lines should be compatible with the brake fluids.

Impact On Vehicle Safety

The approval of brake lines by the DOT has a direct effect on vehicle safety.

Good quality brake lines help ensure:

- Consistent brake performance.

- Reduced risk of brake failures.

- Longevity of the braking system.

Copper-nickel lines are known for their anti-corrosive properties and strength, both critical for vehicle safety. Their compliance with DOT standards makes them an excellent choice for brake line replacements or upgrades.

This alignment with safety protocols ensures peace of mind for drivers, knowing their brake system adheres to rigorous safety standards.

Copper-nickel Brake Lines And Dot Compliance

Copper-Nickel Brake Lines and DOT Compliance are essential for vehicle safety. This type of brake line must meet specific criteria to be considered safe for use on the road.

The Department of Transportation (DOT) sets standards to ensure all brake lines provide reliable performance under various conditions.

Evaluation Process For Brake Lines

The DOT follows a strict evaluation process to approve brake lines.

This includes:

- Testing the brake line’s durability against corrosion and wear.

- Checking the brake line’s strength to withstand high pressure.

- Evaluating the brake line’s flexibility during extreme temperature changes.

Brake lines that pass these tests get a DOT certification, which is marked on the tubing for easy identification.

Copper-nickel’s Alignment With Dot Requirements

Copper-nickel brake lines align well with DOT requirements due to their:

| Property | Benefit |

|---|---|

| Corrosion Resistance | They last longer, even in salt-prone regions. |

| Strength | They can handle high pressure without failing. |

| Flexibility | They remain malleable in cold weather and don’t crack. |

These characteristics ensure copper-nickel brake lines often exceed the DOT’s safety standards. As a result, they are DOT-approved for use in many vehicles, ensuring riders’ safety across the country.

Comparing Copper-nickel With Traditional Materials

If you’re in the market for brake line replacements, you might wonder about the best material for the job.

Copper-nickel alloys are increasingly gaining attention as an alternative to traditional steel brake lines.

Let’s explore the differences and benefits of these materials.

Steel Versus Copper-nickel Brake Lines

- Corrosion Resistance: Copper-nickel brake lines boast superior corrosion resistance. Unlike steel, they don’t rust even in salty conditions.

- Flexibility: Bending and shaping copper-nickel is easier. It reduces installation effort and potential kinking.

- Fittings and Flares: Both materials use standard fittings. Copper-nickel is softer, making flares more accommodating to the seating.

Steel has been the go-to for years, known for its strength. Yet, the rust-resistant nature of copper-nickel is making it a formidable opponent.

Performance And Durability In Diverse Conditions

When it comes to longevity, the type of brake line can make a huge difference.

Here’s how copper-nickel lines perform in various environments:

| Condition | Copper-Nickel | Steel |

|---|---|---|

| Wet and Salty | Resists corrosion | Prone to rust |

| Cold Climates | Remains flexible | Becomes brittle |

| Heat Exposure | Stable performance | Can weaken over time |

Longevity is key in brake line performance. Copper-nickel lines persist through salt, snow, and heat without losing integrity. This makes them a top choice for DOT-approved applications.

Installation And Maintenance Of Copper-nickel Brake Lines

Copper-nickel brake lines are a top choice for vehicle safety. They are DOT approved, which means they meet high standards.

When you install these lines, your car stops better. They also don’t rust, making them last longer. But you need to install and care for them right. Don’t worry; we will tell you how!

Challenges And Best Practices For Installation

Right gear makes the job easy. Always wear safety glasses. You will also need a flaring tool and a tubing cutter.

- Bend carefully: Copper-nickel lines are soft. Use a bending tool to avoid kinks.

- Proper flaring: This makes brake fluid tight. Double flares are best for cars.

Getting the length right is key. Measure twice, cut once!

Ask a friend to help. It’s good to have an extra hand.

Long-term Care For Optimal Performance

Regular checks keep brake lines safe. Look for leaks and damage often.

- Clean: Wipe lines with a cloth to stop rust and dirt buildup.

- Check fittings: Make sure they are snug, not too tight or loose.

When you change brake fluid, check the lines too. They should last a long time with good care.

The Future Of Copper-nickel Brake Lines In The Automotive Industry

Discover the evolution of brake line materials in the automotive industry. Explore how copper-nickel brake lines are making vehicles safer and more reliable.

Advancements In Brake Line Technology

Modern vehicles demand cutting-edge components for optimal safety. The brake line technology is no exception. Recent enhancements focus on improving durability and corrosion resistance.

- Copper-nickel alloys excel in these areas.

- Such brake lines withstand harsh conditions better than traditional steel.

- DOT (Department of Transportation) approves of this evolution due to enhanced safety features.

These advancements are gradually defining the baseline for industry standards.

Trends Driving Copper-nickel Adoption

Several factors contribute to the growing popularity of copper-nickel brake lines.

| Trend | Influence on Adoption |

|---|---|

| Corrosion Resistance | Longer lifespan than steel lines, reducing maintenance costs. |

| Flexibility | Easier installation, saving time and resources. |

| Safety Regulations | DOT approvals assure use in multiple automotive applications. |

| Environmental Factors | Resistance to salt and other elements mean better performance in varied climates. |

Credit: www.amazon.com

Final Word

Navigating the requirements for DOT-approved brake lines is crucial for safety and compliance. Copper nickel alloy lines offer durability and reliability, favored by numerous manufacturers for their distinct advantages.

Before making a final selection, always confirm the compliance of your brake line choices with the latest DOT standards.

Trust in copper nickel’s robustness, but verify its certification to ensure your vehicle’s optimal braking performance.