Have you ever wondered about the correct torque specs for your vehicle’s lug nuts? You’re not alone.

Ensuring your lug nuts are properly tightened is crucial for your safety and vehicle performance. Over-tightening can strip the threads, while under-tightening might lead to loose wheels. These are scenarios you certainly want to avoid. You’ll discover the precise torque specifications for lug nuts, why they matter, and how to achieve them.

You might find that this small detail makes a big difference in your driving experience. Keep reading to ensure your vehicle is road-ready and safe for every journey you take.

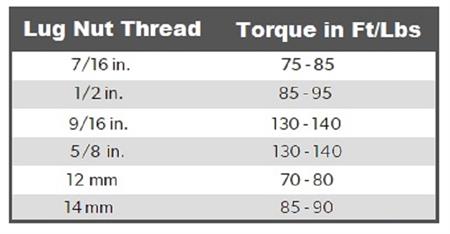

Credit: www.speedwaymotors.com

Torque Importance

Understanding torque specs for lug nuts is crucial for vehicle safety. Proper torque prevents the wheels from coming loose while driving. Incorrect torque can lead to accidents. It can also damage the wheel, rim, or hub. Ensuring the right torque secures the wheel and enhances vehicle performance. It maintains the balance and stability of the car. This section delves into why torque is so important.

Why Torque Matters

Torque keeps lug nuts tight. Proper torque prevents nuts from loosening over time. Loose nuts can cause wheels to wobble. This affects the vehicle’s handling. It can even lead to the wheel detaching. Correct torque ensures nuts stay secure. It reduces the risk of wheel-related accidents.

Impact On Vehicle Performance

Proper torque affects driving quality. It ensures smooth wheel rotation. This enhances the overall driving experience. Incorrect torque can affect the car’s suspension. It may cause uneven tire wear. This impacts fuel efficiency. Correct torque helps in maintaining optimal performance.

Preventing Damage And Wear

Correct torque prevents damage. It avoids stress on wheel components. Over-torquing can damage the wheel hub or rim. Under-torquing can cause excessive wear. Both scenarios lead to costly repairs. Ensuring the right torque minimizes wear. It extends the lifespan of wheel parts.

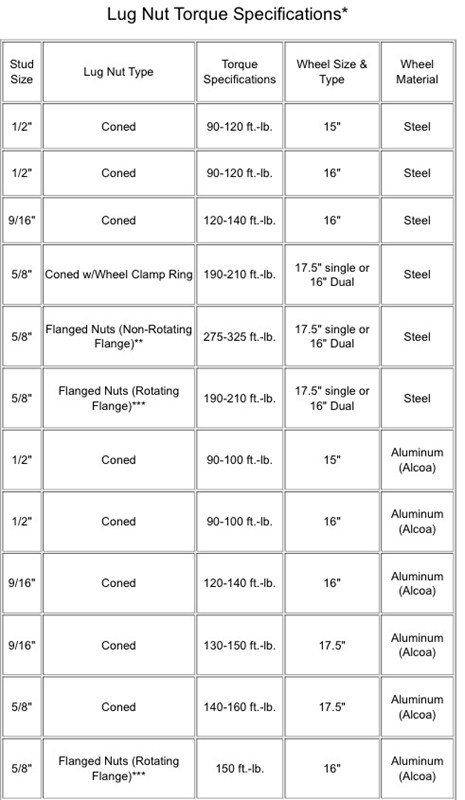

Credit: www.themalibucrew.com

Factors Affecting Torque

When tightening lug nuts, getting the right torque is crucial for your vehicle’s safety and performance. But did you know that various factors can affect how you should set that torque? Understanding these can save you time and prevent costly mistakes. Whether you’re a seasoned mechanic or a weekend DIYer, knowing what influences torque settings can make a world of difference. So, let’s delve into these factors to ensure you’re tightening those lug nuts just right.

Vehicle Type

The type of vehicle you’re working on can significantly impact the torque specs for lug nuts. A compact car might require a different torque setting compared to a heavy-duty truck. For example, a sedan may need around 80 ft-lbs, while a pickup truck might demand 120 ft-lbs or more. Always refer to your vehicle’s manual to find the recommended torque specs. Ignoring this could lead to uneven wear or even a catastrophic wheel failure.

Wheel Material

What your wheels are made of can also affect torque. Alloy wheels, commonly found on performance cars, often require different torque settings than steel wheels. Alloy is softer, so over-tightening can damage the wheel. On the other hand, steel wheels are more forgiving but still require precise torque to avoid issues. If you’ve upgraded your wheels, make sure to check the new torque requirements.

Lug Nut Material

The material of the lug nuts themselves can be a game-changer. Steel lug nuts are the most common and are generally sturdy and reliable. However, aluminum or titanium lug nuts are becoming popular for their lightweight nature. These alternative materials may need different torque settings to ensure they hold up under pressure. Always double-check the specifications if you switch lug nut types.

Weather Conditions

Weather can be an unexpected factor affecting torque specs. Cold temperatures can cause metal to contract, impacting how tight your lug nuts feel. Similarly, extreme heat can expand metal, altering torque. Have you ever found yourself struggling to loosen lug nuts in winter? That’s the metal contracting! Always consider the current climate when checking torque settings, especially if you’re planning a long road trip.

Each factor plays a role in how you should approach tightening your lug nuts. Are you regularly checking and adjusting these settings? It’s a small step that can make a significant difference in your vehicle’s performance and safety. Take a moment to think about the last time you checked your lug nuts—are they properly torqued for your specific conditions?

Standard Torque Specifications

Understanding standard torque specifications is crucial for vehicle safety. Proper torque ensures lug nuts hold wheels securely. Incorrect torque can lead to accidents or wheel damage. Each vehicle type requires specific torque settings. Below, we explore torque specs for different vehicles.

Passenger Cars

Passenger cars usually need torque between 80 and 100 foot-pounds. Check your car manual for precise specifications. Properly torqued lug nuts prevent wheel wobbling or detachment.

Light Trucks And Suvs

Light trucks and SUVs often require higher torque settings. The range is typically 100 to 120 foot-pounds. This ensures stability and safety for larger vehicles. Always verify with the vehicle’s manual.

Heavy-duty Vehicles

Heavy-duty vehicles demand significantly higher torque. Torque specs range from 200 to 250 foot-pounds. These specs are crucial for handling heavy loads. Consult the manufacturer’s guidelines for exact numbers.

Tools For Measuring Torque

When it comes to ensuring your lug nuts are tightened to the correct torque, using the right tools is crucial. Accuracy in torque measurement prevents over-tightening or under-tightening, both of which can lead to dangerous driving conditions. These tools not only help you achieve precision but also make the process more efficient and reliable. Let’s delve into the essential tools for measuring torque and how they can make a difference in your vehicle maintenance.

Torque Wrench

A torque wrench is a staple in any mechanic’s toolkit. It’s designed to apply a specific amount of force to a bolt or nut. The click-type torque wrench is most popular. It emits a clear click sound when you’ve reached the desired torque setting. This audible cue is your signal to stop turning, ensuring you don’t over-tighten the lug nuts.

Imagine the relief of knowing each lug nut on your wheels is perfectly tightened. You can drive confidently, knowing your tires are secure, especially after a tire change. Consider investing in a quality torque wrench for peace of mind.

Digital Torque Adapter

If you already own a ratchet and don’t want to buy a separate torque wrench, a digital torque adapter is your go-to tool. It attaches to your existing wrench, displaying the torque level digitally. This is perfect for tech-savvy individuals who appreciate precise readings.

Ever found yourself second-guessing if you’ve tightened something correctly? A digital torque adapter eliminates that doubt with its accurate digital display. You’ll have the assurance that you’ve done the job right, every single time.

Beam Torque Wrench

For those who prefer simplicity, the beam torque wrench is an ideal option. It uses a straightforward mechanism where a needle points to the torque level on a scale. Its simplicity means fewer parts that can break or malfunction.

Using a beam torque wrench can feel like stepping back in time. Yet, its reliability is unmatched. You might appreciate the straightforwardness and dependability it offers. Sometimes, simple tools are all you need for effective vehicle maintenance.

Have you ever considered how the right tool could save you from future headaches? Ensuring your lug nuts are properly torqued is more than just a task; it’s about safety and reliability. The choice of tool can make all the difference. Which one aligns with your needs? Whether it’s the modern digital adapter or the classic beam wrench, the right choice is just waiting to be made. Choose wisely, drive safely!

Step-by-step Torque Process

Determining torque specs for lug nuts ensures wheel safety and performance. Follow manufacturer guidelines for accurate torque values. Proper tightening prevents wheel damage and improves vehicle handling.

To ensure the safety and performance of your vehicle, proper lug nut torque is crucial. A systematic approach guarantees even pressure distribution on the wheel assembly. This step-by-step torque process will guide you through preparing, tightening, and rechecking the torque of your lug nuts. This ensures your wheels are secure and reliable.Preparation

Before starting, gather all necessary tools. A torque wrench is essential for accuracy. Verify the correct torque specifications for your vehicle. Check your owner’s manual or online resources. Always use clean, undamaged lug nuts. Dirt or damage can affect torque readings. Ensure the vehicle is on a flat, stable surface. This prevents unwanted movement during the process.Tightening Sequence

Start with a crisscross pattern. Tightening opposite lug nuts ensures even pressure distribution. Begin by hand-tightening each lug nut. This prevents cross-threading. Next, use the torque wrench. Set it to the specified torque level. Tighten each lug nut to the correct specification. Follow the crisscross pattern for consistency. This reduces the risk of warped rotors.Rechecking Torque

After all lug nuts are tightened, recheck the torque. Drive the vehicle for a short distance. This allows the wheels to settle. Re-torque each lug nut after driving. This step ensures they remain at the correct specification. Regularly rechecking torque prevents wheel loosening over time. Always prioritize safety and performance by maintaining proper torque.Common Mistakes

Incorrect torque specs for lug nuts can lead to serious issues. Loose lug nuts may cause wheel wobble or even detach. Over-tightening can damage the wheel or studs. Always consult the vehicle’s manual for correct torque values. Proper torque ensures safety and optimal vehicle performance.

When it comes to tightening lug nuts, getting it wrong can lead to serious problems. It’s easy to think that tightening them as much as possible is the best way to go, but that’s not always the case. Many vehicle owners make common mistakes that can compromise safety and performance. Understanding these errors can save you from unnecessary hassle and ensure your wheels stay securely attached.Under-tightening

Under-tightening is a common mistake that can lead to dangerous situations. If lug nuts are not tightened enough, they can loosen over time. Imagine driving down the highway only to feel your car wobbling because a wheel is about to fall off. It’s not just a scary thought—it’s a real risk. Always use a torque wrench to ensure that you’re applying the right amount of force. Check your vehicle’s manual for the recommended torque specs to avoid this mistake. You might think you tightened them well enough by hand, but the wrench doesn’t lie.Over-tightening

Over-tightening is just as problematic as under-tightening. Applying too much force can strip the lug nuts or damage the threads. This mistake can lead to costly repairs, or worse, make it impossible to remove the lug nuts when you need to change a tire. You don’t need to be a bodybuilder to tighten your lug nuts properly. Trust your torque wrench to guide you. It’s all about finding that sweet spot between too loose and too tight.Skipping Recheck

Skipping the recheck is an oversight that can catch you off guard. Even if you’ve tightened your lug nuts correctly, they can loosen after a short drive. Always plan a quick recheck after 50-100 miles. It’s a simple step that can prevent major issues. Have you ever thought you did everything right, only to find out later that something slipped through the cracks? This is one of those moments. A recheck is your safety net. Have you been guilty of any of these mistakes before? Next time you’re working on your vehicle, take a moment to consider these common errors. Your safety depends on it, and a little extra attention can make all the difference.Maintenance Tips

Your vehicle’s safety and performance heavily rely on the condition of its lug nuts. Regular maintenance is key to ensuring these critical components are up to the task. By staying on top of inspections and routine checks, you can prevent costly repairs and enhance your driving experience. Let’s dive into some essential maintenance tips that can make a world of difference.

Regular Inspections

Inspecting your lug nuts regularly is crucial. Take a moment each month to visually check them for rust, wear, or any damage. A quick glance can save you from potential disasters. Once, on a road trip, I noticed a loose lug nut just before hitting the highway. That simple check prevented what could have been a dangerous situation.

Proper Tool Usage

Using the right tools is non-negotiable. A torque wrench is your best friend when it comes to tightening lug nuts. Avoid using power tools, as they may over-tighten and damage the threads. Think about the last time you tried using a regular wrench and ended up with sore wrists. A torque wrench can make this task a breeze.

Routine Torque Checks

Consistent torque checks are essential. Set a reminder to check the torque of your lug nuts every few months. This ensures they remain secure without being overtightened. Have you ever wondered why your car feels wobbly after a tire change? It’s likely due to improper torque settings. Regular checks can eliminate this issue.

Maintaining your lug nuts might seem like a small detail, but it can have a big impact on your driving safety. Are you ready to make these maintenance steps part of your routine?

Faqs On Torque Specs

Understanding the torque specifications for lug nuts can be a game-changer for anyone who owns a vehicle. It’s not just about tightening bolts; it’s about ensuring safety and performance on the road. But what do you do when you’re not sure about the torque specs for your vehicle? This section dives into some frequently asked questions that might help you get a grip on what’s needed to keep your ride safe and sound.

What Are Torque Specs For Lug Nuts?

Torque specs refer to the amount of force used to tighten the lug nuts on your vehicle’s wheels. Each vehicle has specific torque settings, often found in the owner’s manual. Applying the correct torque ensures the nuts are tight enough to hold the wheel securely, but not so tight that they cause damage.

Why Are Torque Specs Important?

Correct torque specs prevent wheel damage and ensure safety. Over-tightening can warp the wheel or snap the bolt. Under-tightening might lead to loose wheels while driving. You want your wheels to stay put, right?

How Do You Measure Torque?

Use a torque wrench to measure torque accurately. This tool allows you to apply a specific force to the lug nuts. It’s essential to use one, as guessing can lead to mistakes. Have you ever tried using just a regular wrench? It’s easy to overdo it.

Can Torque Specs Vary Between Vehicles?

Yes, torque specs vary across different vehicles. Factors include wheel size, material, and manufacturer recommendations. Always refer to your vehicle’s manual for precise details. Imagine using the same force on a compact car and a heavy-duty truck—it just wouldn’t work.

What Happens If You Don’t Follow Torque Specs?

Ignoring torque specs can lead to serious issues. Loose wheels might wobble, causing vibrations or even falling off. Over-tightening can damage the wheel hub or threads. It’s a small step that saves big headaches.

How Often Should You Check Torque Specs?

Check torque specs every time you change or rotate tires. Regular checks are crucial after long drives or carrying heavy loads. Remember, roads are unpredictable, and so is your cargo.

Keeping your lug nuts properly torqued isn’t just a technical task; it’s a practical step towards safety and efficiency. Have you ever had a wheel mishap because of improper torque? It’s a lesson learned the hard way. Ensuring your wheels are securely fastened can mean the difference between a smooth drive and an unexpected roadside dilemma.

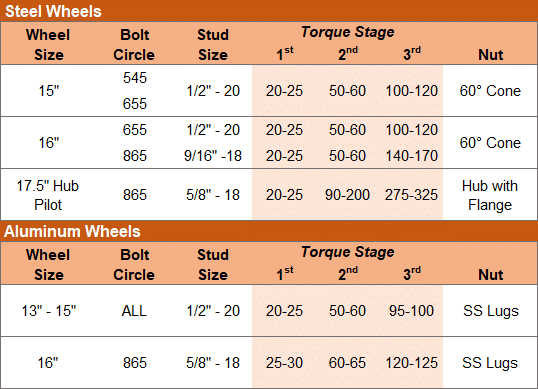

Credit: trailerstationusa.com

Conclusion

Proper torque specs for lug nuts ensure vehicle safety. Tightening them correctly prevents wheel issues. Follow your vehicle’s manual for precise specifications. Always use a torque wrench for accuracy. This tool helps maintain the right pressure. Avoid over-tightening, which can cause damage.

Loose lug nuts can lead to dangerous driving conditions. Regular checks are essential. They keep your wheels secure. Knowing these specs boosts your confidence in car maintenance. It’s a simple task with big benefits. Safety first, always. Keep your ride smooth and trouble-free.

Protect your vehicle with the right torque.