Ever wondered what holds your car’s wheels securely in place? You might have heard about lug nuts, but do you know exactly what they screw onto?

This small yet crucial component is something you rely on every time you hit the road. Picture this: you’re driving down the highway, enjoying the ride, and suddenly, a wheel comes loose. It’s a terrifying thought, isn’t it? But understanding the role of lug nuts and what they attach to can prevent such a nightmare.

You’ll discover the vital connection that keeps your wheels firmly attached, ensuring you drive safely and confidently. Read on to unravel the mystery behind these essential components and their indispensable role in your vehicle’s safety.

Wheel Assembly Basics

When you think about your car’s wheels, you probably don’t give much thought to the nuts and bolts holding them in place. Yet, these small components play a crucial role in ensuring your wheels stay attached to your vehicle. Understanding the basics of wheel assembly can help you appreciate the importance of lug nuts and the role they play in wheel security. Let’s break it down.

Components Of A Wheel Assembly

A wheel assembly consists of several parts working together to keep your vehicle moving smoothly. At its core, it includes the wheel hub, brake rotor, wheel bearings, and the tire itself. Each component has its own function, but together, they ensure that your car drives efficiently.

The wheel hub is the central part that connects to the axle. It acts as the anchor for the rest of the assembly. Wheel bearings help reduce friction, allowing your wheels to spin freely. The brake rotor is crucial for stopping your vehicle safely, while the tire is what makes contact with the road.

Have you ever thought about how all these parts stay connected? Lug nuts are the answer, acting as the tiny heroes keeping everything intact.

Role Of Lug Nuts In Wheel Security

Lug nuts screw onto the wheel hub, securing the wheel and tire assembly to your car. They are more than just fasteners; they are essential for safety. Properly tightened lug nuts prevent wheels from coming off while driving, which could lead to accidents.

Imagine cruising down the highway at high speed. The last thing you want is a loose wheel. Tight lug nuts ensure peace of mind, knowing your wheels are securely attached. Regularly checking lug nuts can be a lifesaver.

Have you ever tightened lug nuts yourself? It’s easier than you might think. Many drivers carry a lug wrench in their trunk for emergencies. Next time you check your tires, take a moment to inspect the lug nuts. Are they tight enough?

How often do you consider the security of your wheels? Lug nuts are small but mighty, playing a vital role in keeping you safe on the road. Don’t overlook their importance the next time you think about your vehicle’s maintenance.

Lug Nuts And Wheel Hubs

Lug nuts play a crucial role in vehicle safety. They secure the wheels to the car. But what do lug nuts actually screw onto? The answer lies in the relationship between lug nuts and wheel hubs. Understanding this connection is key to maintaining your vehicle’s performance.

Function Of Wheel Hubs

Wheel hubs are the central part of the wheel assembly. They hold the wheel in place. The hub connects the wheel to the vehicle’s suspension. It ensures smooth and stable driving. Wheel hubs also house the bearings. Bearings reduce friction and allow the wheel to spin freely.

Connection Between Lug Nuts And Wheel Hubs

Lug nuts attach directly to the wheel hub. They secure the wheel and keep it aligned. Each lug nut screws onto a stud on the hub. This connection ensures the wheel stays attached. Properly tightened lug nuts prevent vibrations. They also reduce the risk of wheel detachment. Regular checks of lug nuts are essential for safety.

Types Of Wheel Studs

Understanding the types of wheel studs is essential for vehicle maintenance. Wheel studs are crucial components that connect wheels to the vehicle hub. They ensure the wheel stays attached while driving. There are different types of wheel studs, each designed for specific needs. Knowing these types can help in choosing the right fit for your vehicle.

Threaded Studs

Threaded studs feature a spiral groove around their body. This groove allows lug nuts to screw onto them securely. These studs are common in many vehicles. They provide a strong and reliable connection. Threaded studs come in various sizes and thread pitches. It’s important to match them with the correct lug nuts.

Press-in Studs

Press-in studs differ from threaded ones. These studs are inserted into the hub and held in place by friction. Press-in studs have a serrated section that grips the hub. They are often used in heavy-duty vehicles. Replacement requires a special tool to press them in or out. They offer a secure fit for high-stress applications.

Benefits Of Different Stud Types

Each stud type offers unique benefits. Threaded studs allow easy replacement of individual components. This makes maintenance simpler and faster. Press-in studs provide a robust hold. They are ideal for vehicles that experience heavy loads. Choosing the right stud type depends on your vehicle’s needs. Consider factors like load, speed, and driving conditions.

Credit: en.wikipedia.org

Material And Design Considerations

Understanding the material and design of lug nuts and studs is vital for vehicle safety. The right combination ensures that wheels stay firmly attached. This section delves into these aspects, highlighting their importance in automotive performance.

Materials Used In Lug Nuts And Studs

Lug nuts and studs are crafted from various materials. Steel is common due to its strength. Chrome-plated steel provides extra corrosion resistance. Aluminum offers lightweight benefits but is less durable than steel. Titanium combines lightness with strength but costs more. Each material choice affects durability and performance.

Impact Of Design On Performance

Design plays a crucial role in lug nut effectiveness. Thread size and pitch ensure proper fit. The shape impacts how nuts distribute pressure across the wheel. Conical designs offer better alignment. Flanged designs increase surface area for a tighter grip. These design features affect how well nuts hold the wheel in place.

Importance Of Proper Installation

Proper installation of lug nuts is crucial for the safety and performance of your vehicle. Without secure lug nuts, your wheels could wobble or even detach while driving. This not only poses a risk to your safety but can also lead to costly damage. Ensuring they are installed correctly is more than just a routine task; it’s an essential step in vehicle maintenance.

Torque Specifications

Every vehicle has specific torque requirements for lug nuts. These specifications are usually found in the owner’s manual. Adhering to these numbers is critical. Over-tightening can warp the brake rotors, while under-tightening risks loosening the wheel. Imagine cruising down the highway and feeling a slight vibration. This could be a sign that your lug nuts aren’t tightened to the correct torque. Checking the specifications and using a torque wrench can prevent this discomfort and potential danger.

Avoiding Common Installation Mistakes

It’s easy to overlook the importance of the installation sequence. Tightening lug nuts in a star pattern ensures even pressure on the wheel. Skipping this can cause uneven torque distribution, leading to wheel imbalance. If you’ve ever felt a shaking steering wheel, improper lug nut installation might be to blame. Also, never use an impact wrench for final tightening. This tool can easily exceed torque specs, damaging the threads and your wheel. Always finish with a manual torque wrench for precision.

Have you ever thought about how often you check your lug nuts? Regular inspections can catch problems early. After tire changes or rotations, it’s wise to re-check the torque. This simple step can prevent future issues and keeps your ride smooth and safe.

Credit: www.carparts.com

Maintenance And Safety Tips

Maintaining lug nuts is crucial for vehicle safety. Proper maintenance ensures your wheels stay securely attached. Regular checks can prevent accidents and costly repairs. This section will guide you through essential maintenance tips for lug nuts.

Regular Inspection Protocols

Inspect lug nuts every few months. Check if they are tight and secure. Loose lug nuts can lead to wheel detachment. Use a torque wrench for accurate tightening. Follow the manufacturer’s recommendations for torque settings. Regular inspections can prevent dangerous situations.

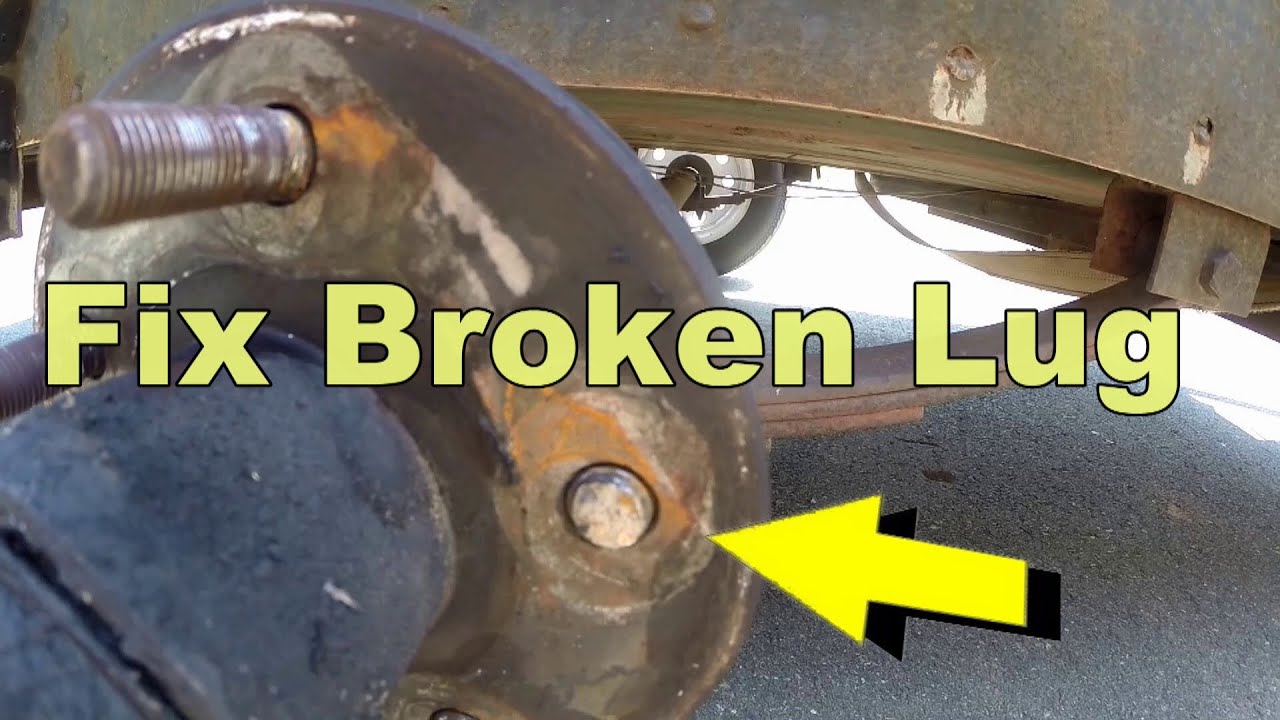

Signs Of Wear And Tear

Look for rust or corrosion on lug nuts. Rust can weaken the metal. Check for cracks or damage. Damaged lug nuts need immediate replacement. Examine the threads for smoothness. Rough threads may indicate wear. Prompt attention to these signs ensures safety.

Innovations In Wheel Fastening

Innovations in wheel fastening have advanced the way lug nuts function. This progress ensures safer and more efficient vehicle performance. Engineers constantly search for better materials and techniques. They aim to improve wheel attachment security. Modern advancements offer durability and ease of use. Let’s explore the latest developments in wheel fastening technologies.

Advanced Materials

Modern lug nuts use new materials for better strength and durability. Traditional steel is now often replaced with alloys. These alloys provide a balance of strength and weight. Lightweight materials reduce overall vehicle weight. This improves fuel efficiency. Advanced coatings on lug nuts resist corrosion. This ensures a longer lifespan for the wheel components.

Technological Enhancements

Technology plays a big role in wheel fastening today. Smart lug nuts monitor and report tension levels. This helps maintain proper wheel attachment. Some systems even alert drivers of loose lug nuts. This reduces the risk of accidents. Torque sensors ensure the correct tightness of each nut. This prevents damage to wheel studs and rims. Additionally, automated tools speed up installation. They offer precise torque settings for each wheel type. These innovations enhance safety and convenience.

Credit: www.youtube.com

Conclusion

Lug nuts play a vital role in securing wheels to vehicles. They screw onto wheel studs, ensuring stability and safety during drives. Always check lug nuts for tightness to prevent wheel issues. Loose lug nuts can lead to accidents, so regular inspection is important.

Choose the right lug nuts for your car’s needs. Consider size, material, and thread pattern. This helps maintain your vehicle’s performance and safety. Properly maintained lug nuts contribute to a smooth driving experience. Stay safe by understanding how they function and checking them often.

Keep your car in top shape with these simple steps.