Have you ever wondered about the torque spec for lug nuts on your vehicle? You’re not alone.

This seemingly small detail plays a crucial role in ensuring your safety on the road. Proper torque specifications help keep your wheels securely attached, prevent costly damage, and maintain smooth handling. If you’ve ever experienced the frustration of a loose wheel or the anxiety of overtightening, you know just how important this is.

We’ll dive into the specifics of lug nut torque, demystifying the numbers and offering practical advice. By the end, you’ll have the confidence to tighten your lug nuts correctly, ensuring peace of mind every time you drive. Keep reading to unlock the secrets of perfect torque and enhance your driving experience!

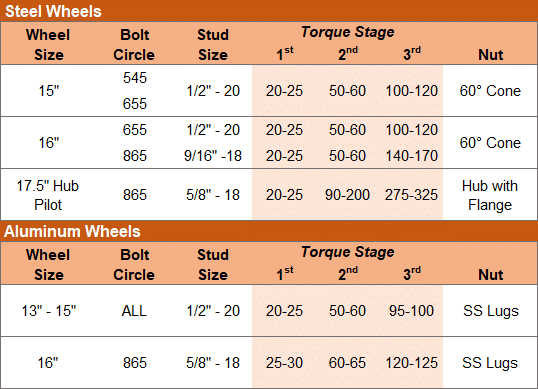

Credit: trailerstationusa.com

Torque Specifications Basics

Understanding torque specifications for lug nuts is essential for vehicle safety. The proper torque ensures secure attachment and prevents wheel damage. Typically, lug nut torque specs range between 80 to 100 foot-pounds. Always check your vehicle manual for the exact specification.

Properly torqued lug nuts enhance driving safety.

Understanding torque specifications is crucial for any vehicle owner or enthusiast. Torque specs are the amount of force you need to tighten lug nuts on your wheels, ensuring they stay secure without damaging the threads. This balance between tightness and safety is essential for optimal vehicle performance.What Is Torque?

Torque is a measure of the twisting force applied to a bolt or nut. Imagine using a wrench to tighten a lug nut. The force you exert determines how securely the nut fastens. Too little, and the wheels might wobble; too much, and you risk damaging the threads.Why Are Torque Specs Important?

Using the correct torque specs prevents wheel-related issues. Properly tightened lug nuts ensure your wheels stay attached, enhancing safety on the road. Over-tightening or under-tightening can lead to costly repairs or dangerous driving conditions.How To Measure Torque

You can measure torque using a torque wrench. This tool lets you apply the exact force required by the manufacturer’s specifications. It prevents over-tightening, ensuring longevity and safety for your vehicle.Common Torque Values

Torque values vary by vehicle make and model. Many cars require lug nuts to be tightened to between 80 to 100 ft-lbs. Always refer to your vehicle’s manual for precise specifications. This ensures you’re applying the correct force every time.Personal Experience

Once, I ignored the torque specs and tightened my lug nuts by feel. The result was a wobbly ride and a damaged wheel hub. Lesson learned: follow the specs to avoid unnecessary hassle and expense.Practical Tips

Always check your vehicle’s manual for torque specs. Invest in a reliable torque wrench. Regularly inspect your lug nuts, especially after tire changes. These steps can prevent mishaps and ensure a smoother drive.Engage With Your Vehicle

Do you know your car’s torque specs? If not, now’s the time to find out. Checking your manual might reveal surprising information that can improve your vehicle’s performance and safety.

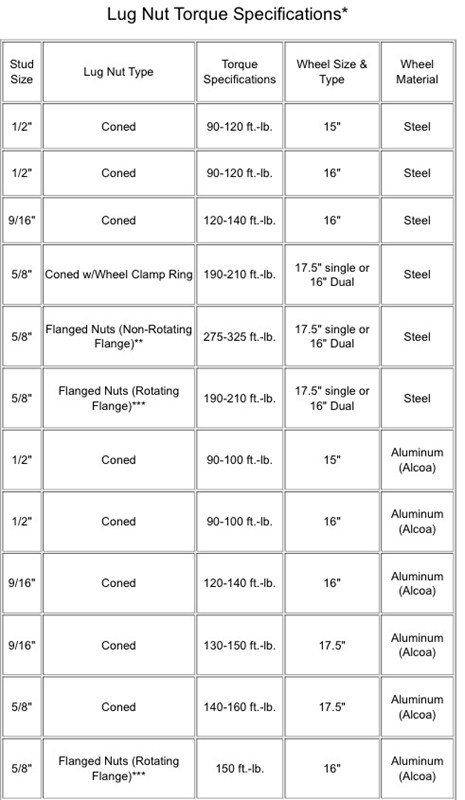

Credit: www.themalibucrew.com

Importance Of Proper Torque

Proper torque for lug nuts ensures safe and secure wheel attachment. Incorrect torque can lead to accidents or vehicle damage. Checking torque specs in your vehicle manual is crucial for maintaining optimal performance.

Understanding the importance of proper torque for lug nuts is crucial for both vehicle safety and performance. It might seem like a minor detail, but getting the torque right can make a significant difference. Imagine driving down the highway and suddenly realizing that your wheel is loose—terrifying, right? Proper torque ensures that your wheels are secure, preventing accidents and unnecessary stress on your vehicle.What Happens When Torque Is Incorrect?

Incorrect torque can lead to various issues. Too loose, and your wheel might wobble or even detach. Too tight, and you risk stripping the threads or damaging the wheel itself. I once helped a friend who had ignored torque specs; his wheel nearly came off while driving. This experience drove home the importance of adhering to the specified torque range.Ensuring Vehicle Stability

Properly torqued lug nuts play a pivotal role in maintaining vehicle stability. When each lug nut is tightened to the recommended specification, it distributes the load evenly across the wheel. This balance helps keep your vehicle stable, especially during sharp turns or sudden stops.Enhancing Tire Longevity

Using the correct torque can extend the life of your tires. Over-torqued or under-torqued lug nuts can cause uneven tire wear. This uneven wear may lead to frequent tire replacements, which is both inconvenient and costly. Wouldn’t you rather spend your money on something more enjoyable than replacing tires?How To Properly Torque Lug Nuts

To ensure you’re applying the correct torque, use a torque wrench. This tool allows you to measure the force applied to the lug nut, ensuring it falls within the manufacturer’s recommended range. Always check your vehicle’s manual for specific torque values.Common Mistakes And How To Avoid Them

One common mistake is using an impact wrench instead of a torque wrench. Impact wrenches can apply too much force, leading to over-torquing. Another mistake is skipping the step of re-checking torque after driving a few miles. Always double-check after a short drive to ensure everything is still secure. Are you guilty of these mistakes? It’s never too late to start doing it right. Proper torque is not just about tightening a lug nut; it’s about ensuring your safety and your vehicle’s longevity. Next time you or someone else changes a tire, remember the importance of proper torque. Your safety is worth those few extra minutes it takes to get it right.Factors Affecting Torque Specs

Understanding the torque specs for lug nuts is crucial. It ensures safety and performance. Torque specs are not universal. They vary based on several factors. Each factor influences how tight the lug nuts should be. Here are the key factors affecting torque specs.

Vehicle Type

The type of vehicle plays a significant role in torque specs. Cars, trucks, and SUVs have different requirements. Larger vehicles often need higher torque. This is due to their greater weight and size. Always refer to the vehicle’s manual for specifics.

Lug Nut Material

The material of the lug nut affects the torque setting. Common materials include steel and aluminum. Steel lug nuts generally require higher torque. Aluminum lug nuts need less torque. This is because they are softer. Using the correct torque prevents damage.

Wheel Type

Wheels come in various materials and designs. Alloy wheels differ from steel wheels in torque needs. Alloy wheels often have specific torque requirements. Steel wheels may have more leeway. Always check the manufacturer’s guidelines for the best fit.

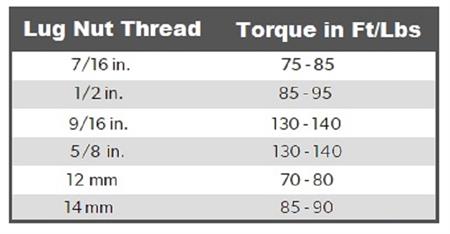

Credit: www.speedwaymotors.com

Tools For Measuring Torque

Measuring torque accurately is crucial for vehicle safety. Proper tools ensure lug nuts are tightened correctly. Incorrect torque can lead to wheel damage or accidents. Using the right tools prevents these issues.

Torque Wrench

A torque wrench is essential for measuring torque. It ensures precise lug nut tightening. It comes in different types, including beam and click wrenches. Beam wrenches are simple and reliable. Click wrenches offer more accuracy. Both types help achieve desired torque values.

Digital Vs. Manual Tools

Digital torque tools provide easy readings. They often have displays showing exact torque measurements. These tools are user-friendly and reduce human error. Manual tools, like beam wrenches, require more skill. They use a scale to show torque levels. Manual tools are often cheaper but need careful handling.

Choosing between digital and manual depends on preference. Digital tools are quick and efficient. Manual tools offer a tactile experience. Each has its benefits for measuring torque.

Common Torque Specs By Vehicle Type

Different vehicle types have specific torque specs for lug nuts. Trucks often need higher torque due to larger wheels. Compact cars typically require lower torque, ensuring safe and secure wheel attachment. Always check your vehicle manual for exact specifications.

Understanding the correct torque specifications for lug nuts based on vehicle type is crucial for both safety and performance. Using the right torque prevents wheel damage and ensures your vehicle runs smoothly. Let’s explore the typical torque specs for different vehicle categories.Passenger Cars

For most passenger cars, the torque spec for lug nuts ranges between 80 to 100 foot-pounds. This range ensures that your wheels are secured without being over-tightened, which can lead to warped brake rotors. Imagine you’re rushing to get to work. You hear a knocking sound coming from your wheels. Proper torque can prevent such unsettling noises and potential accidents.Trucks And Suvs

Trucks and SUVs often require a higher torque, typically between 100 to 150 foot-pounds. These vehicles carry more weight and sometimes tow heavy loads, necessitating a tighter grip. Picture this: You’re on a family road trip with a fully loaded SUV. With the right torque, your wheels will withstand the extra load without a hitch.Motorcycles

Motorcycles generally have a lower torque requirement, around 30 to 50 foot-pounds. The lighter weight of motorcycles means that over-tightening can easily strip the threads or damage the wheel. Think about the thrill of a weekend ride. Ensuring the correct torque keeps your bike agile and responsive, enhancing your riding experience. Have you checked the torque on your vehicle’s lug nuts lately? It’s a small step that makes a big difference in your driving safety. Always refer to your vehicle’s manual for precise specifications.Steps To Ensure Accurate Torque

Ensuring accurate torque for lug nuts involves several key steps. First, check the torque specification for your vehicle. Then, use a calibrated torque wrench. Finally, tighten lug nuts in a crisscross pattern. This prevents uneven pressure on the wheel. Proper torque ensures safety and wheel integrity.

Ensuring that the lug nuts on your vehicle are torqued accurately is crucial for safety and optimal performance. Incorrect torque can lead to wheel imbalance or even cause the wheel to come off while driving. Understanding the steps involved can help you achieve the right torque every time you work on your wheels.Proper Cleaning

Before you begin, make sure the lug nuts and wheel studs are clean. Dirt or rust can interfere with the torque, leading to inaccurate results. Use a wire brush to remove any debris, ensuring a smooth and clean surface. Have you ever noticed how much easier it is to twist a bottle cap when there’s no sticky residue? The same principle applies here. Clean surfaces ensure that the torque reading is consistent and reliable.Correct Sequence

Always follow the correct tightening sequence to distribute pressure evenly. For a five-lug pattern, tighten in a star pattern. For a six-lug pattern, tighten in a crisscross pattern. This sequence prevents warping the wheel, which could lead to uneven pressure. Think of it like tightening the laces on your shoes; you wouldn’t pull one side tight before the other, right?Rechecking Torque

After driving a short distance, it’s important to recheck the torque. Wheels can settle, which might cause the torque to change. Take your torque wrench and ensure each lug nut is still at the correct specification. This step might seem redundant, but it provides peace of mind. Have you ever felt the need to double-check your locked door before bed? Rechecking torque offers similar reassurance and safety. By following these steps, you can ensure your vehicle is ready for the road. What methods do you find most effective when tightening your lug nuts? Share your thoughts and experiences in the comments below!Consequences Of Incorrect Torque

Incorrect torque on lug nuts can lead to serious issues. Proper torque ensures the wheels are securely attached. It prevents unwanted movement during driving. Both over-torquing and under-torquing have their own set of problems. Understanding these consequences is crucial for vehicle safety.

Over-torquing Issues

Over-torquing can damage lug nuts and wheel studs. The excessive force stretches the bolts beyond their limit. This may cause the metal to weaken and break. Threads on the lug nuts can strip. This makes them useless and unsafe. Over-torqued nuts can be a nightmare to remove. This often requires special tools or professional help.

Under-torquing Risks

Under-torquing is equally dangerous. Loose lug nuts can cause the wheel to wobble. This affects the vehicle’s stability and handling. Worst-case scenario, the wheel may detach while driving. This poses a grave risk to both driver and passengers. Regular checks ensure nuts remain tight and secure. Proper torque maintains vehicle safety and performance.

Maintenance Tips For Wheel Safety

Ensuring your vehicle’s wheels are securely fastened is crucial for safety. Lug nuts play a vital role in this. Proper maintenance can prevent accidents and enhance driving performance. Regular checks and adjustments are essential for maintaining optimal torque specs. Keep reading for key maintenance tips.

Regular Checks

Regularly inspect lug nuts for tightness. Use a torque wrench for accuracy. This ensures nuts are not too loose or overly tight. Check the torque specifications in your vehicle manual. Follow these guidelines for safety and performance. Routine inspections help avoid wheel-related issues.

Seasonal Adjustments

Temperature changes can affect lug nut torque. Cold weather might cause them to loosen. In warmer conditions, they could tighten excessively. Adjust torque specs according to the season. Regular checks help adapt to seasonal changes. Keep your wheels safe year-round by adjusting for climate shifts.

Conclusion

Understanding lug nut torque specs is crucial for safety. It ensures wheels stay secure. Tighten each nut evenly for the best results. Follow your vehicle’s manual for specific numbers. Different vehicles have different requirements. Tools like torque wrenches help achieve the right tension.

Proper torque prevents accidents and damage. Regular checks maintain wheel integrity. A simple step saves you from bigger issues. Knowledge of torque specs is essential. It boosts confidence in vehicle maintenance. Keep your ride safe and smooth by adhering to these guidelines.

Your wheels depend on it.